SinkPAD PCBs: Mastering Advanced Thermal Management

With TriWin’s thermoelectric separation technology, you can eliminate critical heat bottlenecks to maximize performance and dramatically extend product lifespan.

What is a SinkPAD PCB? (Thermoelectric Separation Copper Base PCB)

In the world of high-power electronics, and especially high-power LEDs, heat is the primary enemy of performance, reliability, and lifespan. While standard Metal Core PCBs (MCPCBs) improve upon traditional FR-4, their dielectric layer still creates a significant thermal barrier, acting as a bottleneck for heat dissipation.

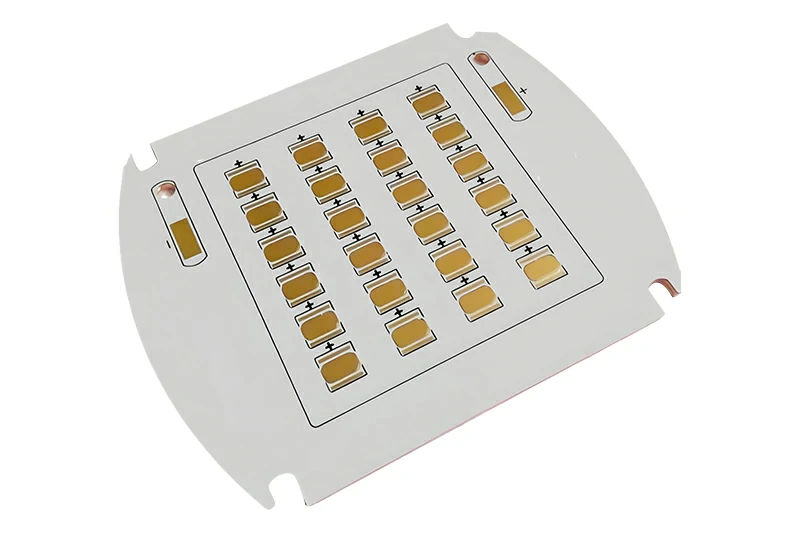

SinkPAD PCB technology, also known as a Thermoelectric Separation Copper Base PCB, revolutionizes thermal management.

Through an innovative manufacturing process, we eliminate the dielectric layer directly beneath the thermal pad of a heat-generating component (like an LED). This creates a direct, uninterrupted thermal path from the component’s heat source straight to the high-conductivity copper base.

This “zero-resistance” design allows for instantaneous heat transfer, achieving an exceptional thermal conductivity of 380-400 W/m.K—an order of magnitude greater than conventional MCPCBs. It fundamentally solves the heat dissipation challenge at its core.

PCB manufacturing

Core Advantages: The TriWin SinkPAD Edge

By integrating TriWin’s SinkPAD PCBs into your design, you gain a decisive competitive advantage

Superior Thermal Performance

The direct thermal path results in the lowest possible thermal resistance at the component interface, dramatically reducing junction temperature and preventing thermal degradation.

Extended Product Lifespan & Reliability

Cooler operating temperatures directly translate to a longer, more reliable service life for your components, reducing light decay in LEDs and preventing premature failure in power electronics.

Unlock Maximum Performance & Brightness

With heat no longer a limiting factor, you can drive your components at higher currents. For LEDs, this means achieving maximum brightness and lumen output without compromising longevity.

Streamlined & Cost-Effective Designs

The unparalleled efficiency of SinkPAD technology can reduce or even eliminate the need for bulky, expensive secondary heatsinks, allowing for more compact, lightweight, and cost-effective product designs.

Engineered for High-Power Applications

Perfectly suited for single high-power components and especially effective for Chip-on-Board (COB) packages, ensuring maximum light output and thermal efficiency.

Primary Applications

SinkPAD PCBs are the ideal thermal management solution for any high-power, high-heat-flux scenario

High-Power LED Lighting

Automotive headlights, professional stage lighting, horticultural grow lights, industrial high-bay fixtures, and architectural lighting.

Automotive Electronics

Mission-critical lighting systems, power control modules, and other components requiring robust thermal reliability.

Power Electronics

High-density power supplies, inverters, converters, and motor drives where efficient heat dissipation is critical for performance.

TriWin’s Custom SinkPAD PCB Capabilities

We understand that every project is unique. Our team is ready to deliver a SinkPAD solution perfectly tailored to your specifications.

| Parameter | Specification (Fully Customizable) | |||||

| Layers | 1 Layer (or custom configurations) | |||||

| Base Material | High-Conductivity Copper | |||||

| Board Thickness | 1.0 mm – 3.0 mm (1.6 mm standard) | |||||

| Copper Thickness | 1 oz – 3 oz (or as required) | |||||

| Surface Finish | ENIG (Immersion Gold), OSP, HASL LF, Immersion Silver, and more. | |||||

| Solder Mask | White, Black, or other specified colors. | |||||

| Structural Design | Custom features including copper convex/concave blocks and parallel thermal/trace layers. | |||||

Why Choose TriWin? Your Expert Manufacturing Partner

At TriWin, our commitment to quality is fundamental for every HDI PCB we produce. We implement rigorous quality control measures throughout the entire manufacturing process

Proven Manufacturing Expertise

Established in 2015, our 10,000-square-meter facility in Huizhou, China, is home to over 220 experienced engineers and technicians. With an annual capacity of 250,000 square meters, we have the scale and expertise to deliver.

International Quality Standards

Our commitment to quality is validated by our certifications, including ISO 9001, IATF 16949 (Automotive), ISO 14001 (Environmental), and UL. We ensure your products meet global standards for safety and reliability.

State-of-the-Art Equipment

We invest in advanced technology, including fully automatic PTH lines, pattern plating lines, and LDI exposure machines, to produce high-precision PCBs efficiently, from rapid prototypes to medium-volume production runs.

Commitment to Premium Materials

Quality starts at the source. We exclusively use Grade-A materials from industry-leading brands like Shengyi, Iteq, and Kingboard, ensuring predictable and reliable performance in every board we ship.

Dedicated Customer Support

We pride ourselves on responsive, efficient communication. Our team offers 24-hour online support and works closely with you to reduce costs, enhance efficiency, and provide attentive after-sales service.