In manufacturing and PCB design, fasteners must sit flush or below the surface for aesthetics, functionality, or strength. Using the wrong hole type can lead to weak joints, poor aesthetics, or assembly failures. Understanding the differences between counterbore and countersink holes ensures your project’s success.

When I started in PCB design, I mixed up counterbore and countersink holes, causing errors in our fabrication drawings. A misstep once delayed a project because screws didn’t fit properly. Learning their unique roles transformed my approach, making our designs more reliable and efficient. Let’s explore what sets these holes apart.

Table of Contents

- What Are Countersink Holes?

- What Are Counterbore Holes?

- How Do Countersink and Counterbore Holes Differ?

- When Should You Use Countersink Holes?

- When Should You Use Counterbore Holes?

- How to Specify Countersink and Counterbore Holes in PCB Design

What Are Countersink Holes?

Countersink holes are a go-to in machining and PCB design, shaping how fasteners integrate with surfaces. Their unique design makes them essential for specific applications.

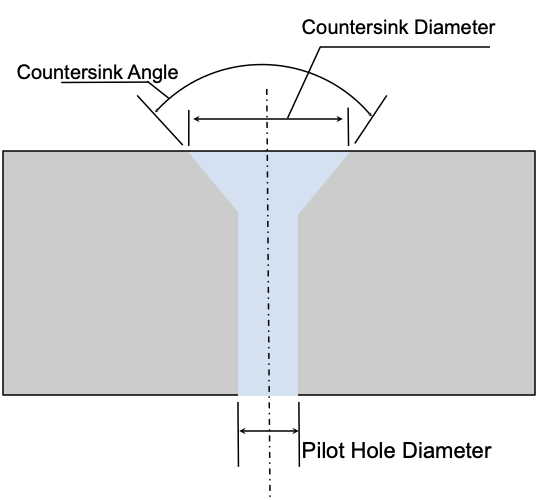

Countersink holes are conical-shaped holes that allow flat-head screws to sit flush with or below the material’s surface. They are denoted by the symbol ⌵ in engineering drawings.

Definition and Shape

Countersink holes have a tapered, cone-shaped profile with angles typically ranging from 60° to 120°, with 82° and 90° being the most common. This shape matches the underside of flat-head screws, ensuring a snug fit. In PCBs, they’re often used on outer layers for a smooth, flush finish, critical for aesthetics or to avoid snagging components.

Common Applications

Countersink holes shine in applications requiring a sleek appearance or minimal protrusion. For example, in a smartphone PCB, countersink holes secure components without adding bulk, maintaining a slim design. In woodworking, they’re used to hide screws under plugs for a polished look. Their tapered design, however, can reduce holding strength due to uneven force distribution.

Creation Process

These holes are made using countersink bits or endmills, starting with a pilot hole followed by a conical enlargement. The process is relatively fast but requires precision to match the screw’s angle. In PCBs, countersinking can be riskier due to material removal, potentially weakening the board.

Practical Advice: Ensure the countersink angle matches the screw head to avoid gaps or instability. Verify with your manufacturer to prevent over-drilling.

What Are Counterbore Holes?

Counterbore holes offer a robust solution for fastening, especially when strength or larger fasteners are needed. Their design supports heavy-duty applications.

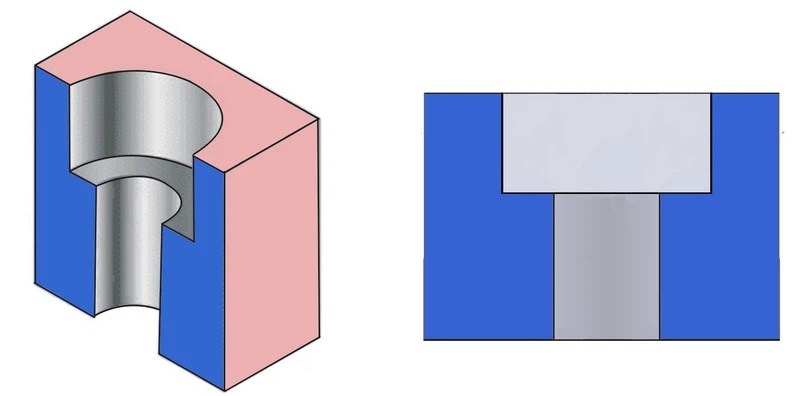

Counterbore holes are cylindrical with a flat bottom, designed to house larger fasteners or washers flush with the surface. They are represented by the symbol ⌴.

Definition and Shape

Counterbore holes feature straight, parallel walls and a flat bottom, providing a stable seat for fasteners like socket-head screws or bolts. Unlike countersinks, they don’t taper, which enhances their holding strength by distributing force evenly across a larger area.

Common Applications

In PCBs, counterbore holes are ideal for internal layer connections or high-stress environments like automotive electronics. For instance, in an electric vehicle’s battery management system, counterbore holes secure PCBs against vibration. In general machining, they’re used in construction or machinery for lag bolts or when washers are needed for added stability.

Creation Process

Counterbore holes are created by drilling a pilot hole and then enlarging the top with a counterbore cutter. This process is straightforward but involves more steps than countersinking, ensuring a precise flat-bottomed cavity. In PCBs, counterboring is preferred for its minimal material removal, preserving board strength.

Practical Advice: Specify the exact diameter for the counterbore to accommodate washers or larger fastener heads. Check manufacturer capabilities for precision.

How Do Countersink and Counterbore Holes Differ?

Choosing between countersink and counterbore holes requires understanding their distinct characteristics. Let’s break down what sets them apart.

The primary differences between countersink and counterbore holes are their shape, depth, holding strength, and applications. Countersink holes are tapered and deeper, ideal for flat-head screws and flush finishes, while counterbore holes are cylindrical with a flat bottom, suited for larger fasteners and high shear strength.

Comparison Table

| Feature | Countersink Hole | Counterbore Hole |

|---|---|---|

| Shape | Conical, tapered sides (⌵) | Cylindrical, flat bottom (⌴) |

| Depth | Deeper to allow screw to sink | Shallower but wider |

| Holding Strength | Lower, uneven force distribution | Higher, even force distribution |

| Typical Use | Flat-head screws, flush finishes | Larger fasteners, washers, high shear strength |

| Pilot Hole Size | Smaller | Larger |

| Creation Method | Countersink bit or endmill | Pilot hole with counterbore cutter |

| PCB-Specific Notes | More material removed, riskier to drill | Less material removed, stronger for internal use |

Detailed Differences

- Shape: Countersink holes are conical, with angles like 82° or 90°, matching flat-head screws. Counterbore holes are cylindrical, with straight walls and a flat bottom for larger fasteners.

- Depth: Countersinks are deeper to recess screws fully, while counterbores are shallower but wider to accommodate washers or bolt heads.

- Holding Strength: Counterbores offer superior strength due to even force distribution, ideal for high-stress applications. Countersinks, with tapered sides, are less robust.

- Applications: Countersinks are used for aesthetic or low-profile needs, like in consumer electronics. Counterbores are preferred in automotive or machinery for stronger joints.

- PCB Considerations: Countersinking removes more material, potentially weakening PCBs, and is riskier during assembly. Counterboring preserves board integrity and is often favored by manufacturers.

Practical Advice: Use a comparison checklist when designing to ensure the hole type aligns with your project’s strength and aesthetic needs.

When Should You Use Countersink Holes?

Selecting the right hole type depends on your project’s goals, from appearance to structural demands. When are countersink holes the best choice?

Use countersink holes when you need flat-head screws to sit flush with the surface, especially for aesthetic reasons or in thin materials, and when high shear strength isn’t critical.

Aesthetic and Low-Profile Needs

Countersink holes are perfect for applications where a smooth surface is essential. For example, in a laptop PCB, countersink holes ensure screws don’t protrude, maintaining a sleek design. In woodworking, they allow screws to be hidden under plugs for a polished finish.

Thin Materials

In PCBs mounted to thin panels, countersinks prevent over-penetration that could damage the board. They’re ideal when the material thickness limits the depth of the hole.

Trade-Offs

The tapered design removes more material, which can weaken the PCB, and drilling requires precision to avoid damage. They’re less suitable for high-stress environments due to lower holding strength.

Practical Advice: Match the countersink angle to the screw head and test the depth to ensure a flush fit without compromising the board.

When Should You Use Counterbore Holes?

Counterbore holes are the go-to for projects needing robust fastening solutions. When should you opt for them?

Use counterbore holes for applications requiring high shear strength, larger fasteners, or washers, such as in construction, machinery, automotive, or internal PCB connections.

High Shear Strength

Counterbore holes distribute force evenly, making them ideal for high-stress applications. In an industrial control system PCB, counterbores secure components against vibration and mechanical stress.

Larger Fasteners and Washers

Their wider, flat-bottomed design accommodates larger bolts or washers. For example, in an automotive radar system, counterbore holes ensure secure fastening of PCBs within rugged enclosures.

PCB-Specific Benefits

Counterbores remove less material, preserving PCB strength, and are easier to drill accurately, reducing assembly risks. They’re preferred for internal layer connections where durability is key.

Practical Advice: Specify the counterbore diameter to fit your fastener and washer, and confirm with your manufacturer to ensure compatibility.

How to Specify Countersink and Counterbore Holes in PCB Design

Getting the specifications right is critical to avoid manufacturing errors and ensure your PCB performs as intended.

In PCB design, specify countersink and counterbore holes in the fabrication drawing or mechanical layer of Gerber files, including side (top/bottom), plated/non-plated status, primary drill diameter, major diameter, depth, and for countersinks, the taper angle.

Specification Steps

- Choose Hole Type: Decide based on fastener type and application (flush finish vs. high strength).

- List Dimensions:

- Both: Side, plated/non-plated, primary drill diameter, major diameter, depth.

- Countersink: Taper angle (e.g., 82°, 90°).

- Document Clearly: Include specifications in both fabrication drawings and Gerber files’ mechanical layer to avoid miscommunication.

- Verify with Manufacturer: Ensure your specs align with their drilling capabilities.

Common Pitfalls

- Omitting the taper angle for countersinks.

- Not specifying the side (top/bottom) of the hole.

- Forgetting to indicate if walls are plated, which affects electrical connectivity.

Practical Advice: Use PCB design software to simulate hole placement and consult your manufacturer early to avoid costly rework.

Conclusion

Countersink and counterbore holes serve distinct purposes in PCB design and manufacturing. Countersink holes, with their conical shape, are ideal for flush finishes in aesthetic or thin-material applications, while counterbore holes, with their cylindrical, flat-bottomed design, excel in high-strength scenarios involving larger fasteners or washers. Their differences in shape, depth, strength, and use cases make them suited for specific needs, from consumer electronics to automotive systems. Proper specification in design files ensures accurate manufacturing, enhancing reliability and performance.

At Triwin, we specialize in high-quality PCB manufacturing, ensuring precise drilling of countersink and counterbore holes to meet your project’s needs. Visit Triwin to learn how we can support your next PCB project.