Aluminum PCBs, also known as metal-based PCBs, are a type of printed circuit board (PCB) that incorporates a metal substrate, often aluminum, as its base. The metal substrate offers enhanced thermal conductivity, making aluminum PCBs an ideal solution for applications requiring efficient heat dissipation. In this article, we will explore the features, advantages, applications, and manufacturing process of aluminum PCBs.

What is Aluminum PCB?

Aluminum PCBs are characterized by their unique structure, which includes a metal base—usually aluminum—underneath the PCB’s copper traces. This design significantly enhances the board’s ability to conduct heat away from sensitive electronic components, making them essential for high-power and high-performance applications.

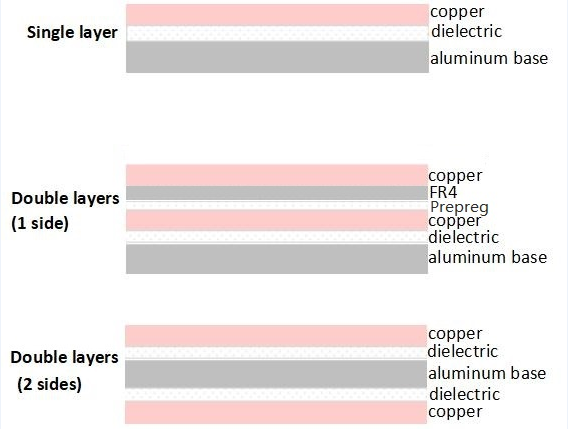

Aluminum PCBs consist of three layers:

- Copper Layer: This is where the electrical components are mounted.

- Dielectric Layer: A non-conductive layer that provides insulation between the copper and the metal substrate.

- Aluminum Base Layer: This layer helps to dissipate heat effectively, ensuring components operate within their optimal temperature range.

Advantages of Aluminum PCBs

- Superior Heat Dissipation: Aluminum PCBs excel in thermal management. The aluminum base allows for rapid heat transfer away from components, preventing overheating. This is crucial for applications like LEDs, where excess heat can degrade performance and longevity.

- Lightweight and Durable: Aluminum is lightweight yet highly durable, making it ideal for industries that require robust but low-weight solutions. These boards are also resistant to environmental factors like moisture and oxidation.

- Cost-Effective Manufacturing: The production cost of aluminum PCBs is relatively low, making them a cost-effective solution for many applications without compromising on performance.

- Enhanced Electrical Performance: The aluminum base can also improve the electrical performance of circuits by reducing the risk of electrical noise and improving signal integrity.

- Better Mechanical Strength: Aluminum provides high mechanical strength, which makes aluminum PCBs more resistant to damage during handling or installation.

Applications of Aluminum PCBs

Aluminum PCBs are commonly used in various industries due to their heat management capabilities and performance benefits. Some of the key areas of application include:

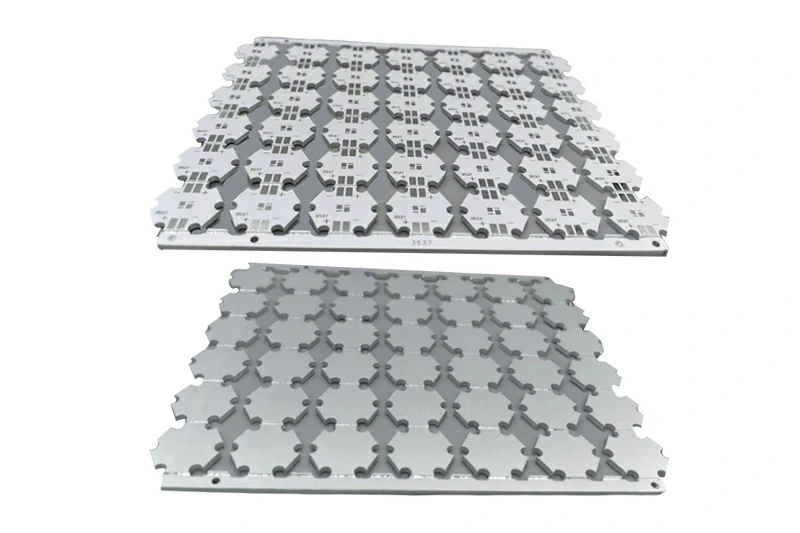

- LED Lighting: Aluminum PCBs are predominantly used in LED applications, including LED lamps, light panels, and automotive lighting. LEDs generate significant amounts of heat, which can be effectively managed with aluminum PCBs, enhancing the performance and lifespan of the LEDs.

- Power Supplies and Converters: In power electronics such as power supplies, converters, and inverters, the thermal management provided by aluminum PCBs ensures efficient operation, especially under high power loads.

- Automotive Electronics: Aluminum PCBs are also widely used in automotive electronics, where reliability and heat dissipation are crucial for the safety and performance of components like sensors, control units, and lighting systems.

- Industrial Equipment: Aluminum PCBs are used in industrial control systems, motors, and other machinery where heat management is critical to maintaining optimal operation.

- Consumer Electronics: In devices such as smartphones, tablets, and laptops, aluminum PCBs contribute to efficient heat dissipation, ensuring that sensitive components remain at optimal operating temperatures.

Manufacturing Process of Aluminum PCBs

The manufacturing of aluminum PCBs involves several key steps to ensure quality and performance:

- Design and Layout: The PCB design is first created using PCB design software. The design includes the placement of components and the routing of electrical traces. This step is crucial for ensuring the proper function of the board.

- Material Selection: High-quality materials are chosen for both the copper and dielectric layers. The metal substrate, typically aluminum, is selected based on its thermal conductivity and mechanical properties.

- Etching Process: The copper layer is etched to form the electrical traces. The etching process requires precision to avoid damage to the PCB and ensure optimal electrical performance.

- Dielectric Layer Lamination: The dielectric layer is then laminated onto the copper traces. This layer provides insulation and electrical isolation between the copper and the aluminum substrate.

- Assembly: Once the PCB is ready, components such as resistors, capacitors, and ICs are mounted onto the board. The board is then subjected to soldering, either through wave soldering or surface mount technology (SMT).

- Inspection and Testing: After assembly, the aluminum PCB undergoes rigorous inspection and testing. This ensures that the board is free from defects and meets the required performance standards.

Why Choose Aluminum PCBs?

Aluminum PCBs are a go-to solution for applications requiring efficient heat management, durability, and high electrical performance. Their versatility and cost-effectiveness make them an attractive option for industries such as LED lighting, power electronics, and automotive systems.

For businesses looking for reliable and high-quality aluminum PCBs, partnering with a trusted PCB manufacturer like TriWin Circuits ensures you receive products designed to meet the demands of your applications. Whether you need standard aluminum PCBs or specialized designs, TriWin’s expertise can help deliver optimal results with fast turnaround times and cost-effective solutions.

Conclusion

Aluminum PCBs provide significant benefits in terms of heat dissipation, mechanical strength, and cost-effectiveness. They are widely used across multiple industries, from LED lighting to automotive electronics. Understanding their structure, applications, and manufacturing process can help you make informed decisions when selecting the right PCB for your projects.If you are looking for high-quality aluminum PCBs, TriWin Circuits is dedicated to providing reliable and effective solutions that meet the unique needs of your business.