In the fast-paced world of electronics, a tiny misalignment in a printed circuit board (PCB) can cause devices to fail, leading to costly delays. Fiducial marks solve this problem. These small copper pads on a PCB act as reference points, guiding automated machines to place components with pinpoint accuracy.

When I started in PCB design, I overlooked fiducial marks, thinking they were minor details. Then, an assembly line stopped because of a misaligned board, costing hours of rework. That day, I learned fiducial marks are the unsung heroes of precision, ensuring every component lands exactly where it belongs.

Table of Contents

- What Are the Types of Fiducial Marks?

- How Do Fiducial Marks Work in PCB Assembly?

- Where Should Fiducial Marks Be Placed on a PCB?

- What Are the Standard Sizes for Fiducial Marks?

- Why Are Fiducial Marks Important for Modern PCB Manufacturing?

What Are the Types of Fiducial Marks?

Imagine navigating a city without landmarks—PCB assembly without fiducial marks is just as chaotic. These markers guide machines to place components correctly. Let’s explore the two main types that ensure precision.

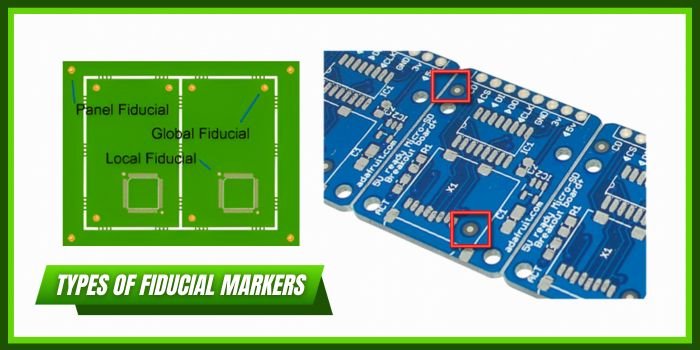

There are two primary types of fiducial marks: global and local. Global fiducial marks align the entire PCB, while local fiducial marks ensure precise placement for specific components, like ball grid arrays (BGAs, components with an array of solder balls) and quad flat no-leads (QFNs, surface-mount packages with leads on all four sides).

Global Fiducial Marks

Global fiducial marks sit at the PCB’s corners or on panel rails for multi-board assemblies. They help machines determine the board’s orientation and position. Industry standards suggest using at least two global fiducials, placed diagonally opposite, but three form a plane for better accuracy. For example, in an automotive radar PCB, global fiducials at the bottom-left and top-right corners ensure correct alignment. The theoretical basis is geometric: these marks establish a coordinate system, reducing rotational errors. Practically, they streamline setup and ensure consistency across panels, saving time in high-volume production.

Local Fiducial Marks

Local fiducial marks are placed near components needing high precision, such as BGAs or QFNs. They fine-tune alignment, ensuring each pin or ball matches its pad perfectly. For instance, in a medical device PCB with a QFN microcontroller, two local fiducials diagonally across the footprint ensure accuracy. The trade-off is board space—local fiducials take up room, but their precision is vital for fine-pitch components (below 1 mm). Without them, misalignments could lead to device failures.

Comparison Table: Global vs. Local Fiducial Marks

| Feature | Global Fiducial Marks | Local Fiducial Marks |

|---|---|---|

| Purpose | Align the entire PCB | Align specific components |

| Placement | Corners of PCB or panel | Near fine-pitch components |

| Number | Typically 2-3 per board | Usually 2 per component |

| Size | Standard (e.g., 1 mm) | Can be smaller if space-limited |

Practical Advice: Place global fiducials far apart for maximum accuracy. For local fiducials, check with your manufacturer to ensure compatibility with their vision systems.

How Do Fiducial Marks Work in PCB Assembly?

Ever wondered how machines place thousands of tiny components on a PCB with such precision? Fiducial marks are like landmarks on a map, guiding assembly machines to navigate the board accurately. Let’s dive into how they work. Now that we know the types, let’s see how they function in the assembly process.

During PCB assembly, machines use cameras to detect fiducial marks. These marks help calculate the PCB’s exact position and orientation, allowing machines to adjust component placement for perfect alignment.

The Role of Computer Vision

Assembly machines, like pick-and-place systems, use cameras to capture high-resolution images of the PCB. Fiducial marks, typically round copper pads without solder mask, provide high contrast for easy detection. For example, in a consumer electronics PCB, three global fiducials help the machine orient the board correctly. The vision system identifies the marks’ centroids, calculating their coordinates to establish the board’s position. This minimizes errors from slight misplacements on the conveyor. The trade-off is ensuring fiducials remain unobstructed, requiring careful layout planning.

Alignment Process

Once detected, fiducial marks allow the machine to adjust component placement coordinates. For instance, in a telecommunications PCB, global fiducials align the board, while local fiducials near a BGA ensure precise placement. The process involves detection, identification, calculation, adjustment, and placement. This systematic approach ensures consistency, especially in high-volume production where speed and accuracy are critical.

Steps in Using Fiducial Marks

- Detection: Cameras capture the PCB image.

- Identification: Vision systems locate fiducial marks.

- Calculation: Determines PCB position and orientation.

- Adjustment: Updates component placement coordinates.

- Placement: Places components accurately.

Practical Advice: Test your PCB design with your manufacturer’s vision system specifications to ensure fiducial marks are detectable.

Where Should Fiducial Marks Be Placed on a PCB?

Placing fiducial marks is like setting up signposts on your PCB—they need to be visible and strategically positioned. Where exactly should they go to ensure effective assembly? Let’s explore the best practices.

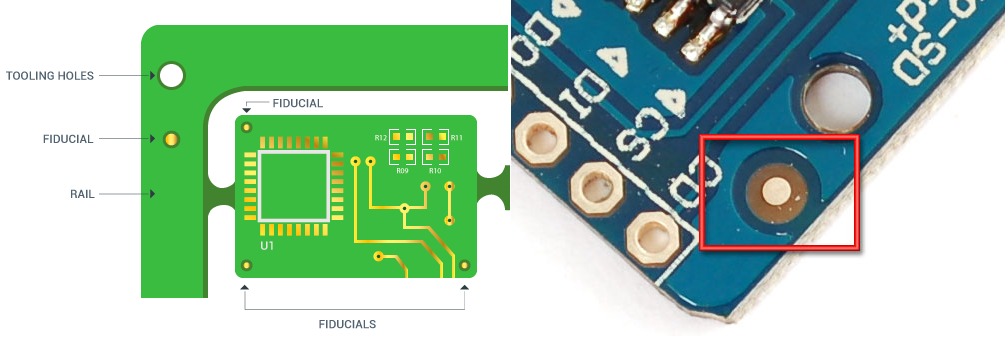

Global fiducial marks should be placed at the PCB’s corners in a non-symmetrical pattern to avoid orientation errors. Local fiducial marks should be near components like BGAs or QFNs for precise alignment.

Placement Guidelines for Global Fiducials

Global fiducials should be at least at two opposite corners, such as bottom-left and top-right, to define the board’s orientation. A non-symmetrical pattern prevents 180-degree rotation errors. For example, in an industrial control PCB, three fiducials in an L-pattern ensure robust alignment. Geometrically, three points define a plane, maximizing accuracy. They should be at least 0.3 inches from the board edge to avoid damage during handling. The trade-off is balancing placement with space constraints.

Placement Guidelines for Local Fiducials

Local fiducials are placed near fine-pitch components, typically within a few millimeters, to ensure precise alignment. For instance, in a medical imaging PCB, two local fiducials near a BGA ensure perfect pin alignment. The challenge is fitting them in dense layouts without obstructing routing paths. Ensure they’re not covered by solder mask or components for clear visibility.

Practical Advice: Use PCB design software to simulate fiducial placement and verify with your manufacturer to avoid conflicts.

What Are the Standard Sizes for Fiducial Marks?

Fiducial mark sizes might seem like a small detail, but getting them right is crucial for machine compatibility. What are the standard sizes, and why do they matter? Let’s find out.

The standard size for fiducial marks is a 1 mm diameter copper pad with a 2-3 mm solder mask opening. Consistent sizing across all fiducials ensures accurate detection and alignment.

Size Variations and Their Impacts

Fiducials smaller than 1 mm may be hard to detect, especially under varying lighting, risking alignment errors. Larger fiducials (up to 3 mm) are easier to spot but take up more space, a concern in compact designs like wearable device PCBs. Inconsistent sizes can confuse vision systems, causing calibration issues. The optical recognition principle requires uniform size for reliable detection.

IPC Recommendations

The IPC (IPC Standards) recommends fiducial diameters between 1 mm and 3 mm, with a solder mask opening twice the diameter. Size variation should not exceed 25 microns. For example, in an automotive lighting PCB, adhering to these standards ensures compatibility with high-speed assembly lines.

Fiducial Size Guidelines Table

| Parameter | Recommended Value |

|---|---|

| Fiducial Diameter | 1 mm |

| Solder Mask Opening | 2-3 mm |

| Shape | Round |

| Material | Exposed copper |

Practical Advice: Confirm fiducial size requirements with your assembly partner to match their equipment.

Why Are Fiducial Marks Important for Modern PCB Manufacturing?

In today’s world of compact, complex electronics, precision is everything. Why are fiducial marks so critical in modern PCB manufacturing? Let’s explore their impact.

Fiducial marks ensure accurate component placement, reducing assembly errors, improving production yield, and supporting high-density, fine-pitch PCBs in industries like automotive and medical.

Impact on Assembly Accuracy

Without fiducials, machines rely on less precise methods like board edges, risking errors in high-density designs. Fiducials provide a direct reference, ensuring components are placed correctly. For example, in a smartphone PCB, fiducials ensure tiny 0201 resistors are accurately placed, preventing short circuits. Coordinate-based alignment minimizes errors, enhancing reliability.

Benefits in High-Volume Production

In high-volume settings, like automotive electronics production, fiducials enable fast, accurate component placement across thousands of boards, reducing rework. For instance, in advanced driver-assistance systems (ADAS), fiducials ensure consistent quality. The design effort to include fiducials is outweighed by improved yield and efficiency.

Practical Advice: For high-volume projects, use three global fiducials and local fiducials for fine-pitch components to maximize yield.

Conclusion

Fiducial marks are the backbone of precise PCB assembly, guiding machines to place components accurately in everything from smartphones to medical devices. By understanding their types, functionality, placement, and standards, designers can create boards that meet the demands of modern electronics. Global fiducials align entire boards, while local fiducials ensure precision for complex components. Following IPC standards for size and placement optimizes compatibility with assembly equipment, reducing errors and boosting yield.

At Triwin, we integrate fiducial marks into every PCB design to ensure precision and reliability. Our expertise in manufacturing high-quality PCBs for industries like automotive, medical, and consumer electronics ensures your projects succeed. Learn more at Triwin.