Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, enabling the interconnection of components compactly and efficiently. With advancements in technology, various types of PCB have been developed to meet the diverse needs of industries ranging from consumer electronics to aerospace. Understanding the different types of PCB, their definitions, applications, advantages, and limitations is essential for engineers and designers in selecting the most suitable solution for their projects. In this article, we will delve into the key types of PCB, providing detailed insights to help guide your choices in electronic design and manufacturing.

1. Single-Sided PCBs

Definition:

A single-sided PCB consists of a single layer of conductive material (usually copper) laminated onto one side of a non-conductive substrate, such as FR-4. The conductive pathways are etched from the copper layer, forming traces that connect various electronic components mounted on the same side. This type of PCB is characterized by its simplicity and straightforward design, making it the most basic form of printed circuit boards.

Applications:

Used in low-density designs where space is not a significant constraint, commonly found in devices like calculators, basic LED circuits, household appliances, and toys.

Advantages:

- Cost-effective manufacturing process

- Easy assembly and testing due to an uncomplicated layout

Limitations:

- Design restricted to one side, limiting the number of components

- Larger board sizes for more complex circuits

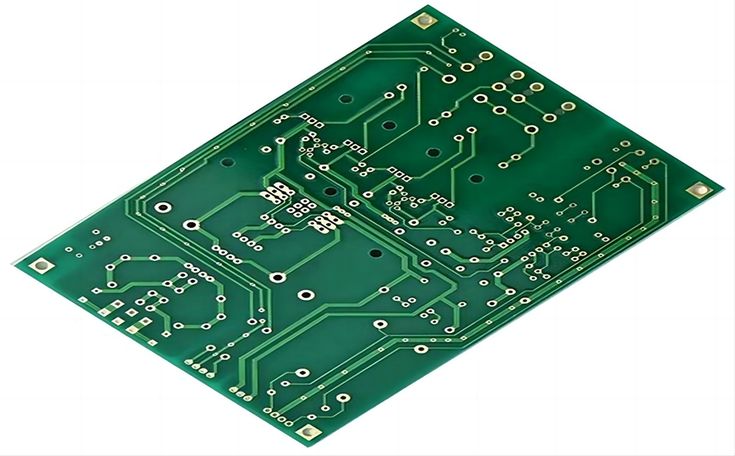

2. Double-Sided PCBs

Definition:

A double-sided PCB features conductive layers on both sides of the substrate, allowing greater complexity in circuit layouts. Components can be mounted on both sides and interconnected through plated through holes (vias).

Applications:

Widely used in more complex electronic devices such as power supplies, audio equipment, communication devices, and consumer electronics like smartphones and tablets.

Advantages:

- Higher component density and intricate circuit designs

- Better performance in compact devices

Limitations:

- More complex manufacturing process, leading to higher costs

- Requires careful design to ensure proper alignment during assembly

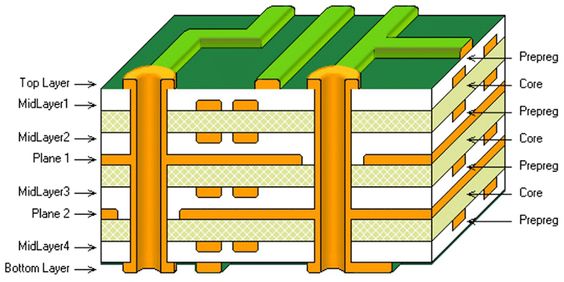

3. Multilayer PCBs

Definition:

Multilayer PCBs consist of three or more layers of conductive pathways separated by insulating layers (prepreg). These layers are bonded together under heat and pressure to create a compact structure.

Applications:

Essential in high-performance applications like computers, servers, telecommunications equipment, medical devices (e.g., MRI machines), and aerospace technology.

Advantages:

- Supports intricate routing for high-density designs

- The compact nature allows for smaller end products without sacrificing performance

Limitations:

- Significantly more expensive and complex to manufacture

- Design changes can be more challenging

4. Rigid PCBs

Definition:

Rigid PCBs are constructed from a solid substrate material that provides structural integrity and cannot be bent or flexed. These boards can be designed as single-sided, double-sided, or multilayer configurations.

Applications:

Used in applications requiring durability and stability, such as computers, industrial machinery controls, automotive electronics, and medical devices (e.g., diagnostic equipment).

Advantages:

- Excellent mechanical support for components

- Easier assembly due to stable structure

Limitations:

- Lack of flexibility in design changes once manufactured

- May limit application in space-constrained environments

5. Flexible PCBs

Definition:

Flexible PCBs utilize flexible substrates like polyimide or polyester that allow bending or twisting without damage. These boards can have multiple layers but retain the ability to conform to various shapes.

Applications:

Ideal for applications where space is limited or movement is required, such as wearable technology (smartwatches), mobile devices, automotive electronics, and medical devices (catheters).

Advantages:

- Lightweight and adaptable for innovative designs

- Reduces assembly complexity by eliminating the need for connectors

Limitations:

- More expensive than rigid boards

- May have limitations in component density compared to multilayer rigid boards

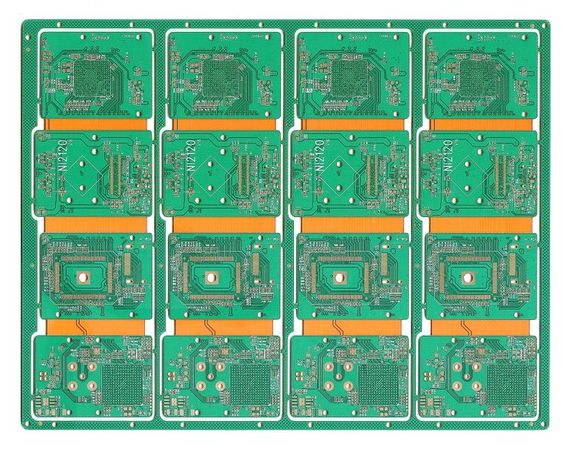

6. Rigid-Flex PCBs

Definition:

Rigid-flex PCBs combine elements of both rigid and flexible circuit designs into a single board structure. Certain sections remain rigid while others can flex.

Applications:

Commonly used in compact electronic assemblies like smartphones, tablets, drones, aerospace applications (e.g., avionics), and military electronics.

Advantages:

- Provides mechanical support while allowing flexibility

- Reduces assembly time by combining multiple board types

Limitations:

- Complex manufacturing process leading to higher costs

- Precise alignment is required during production

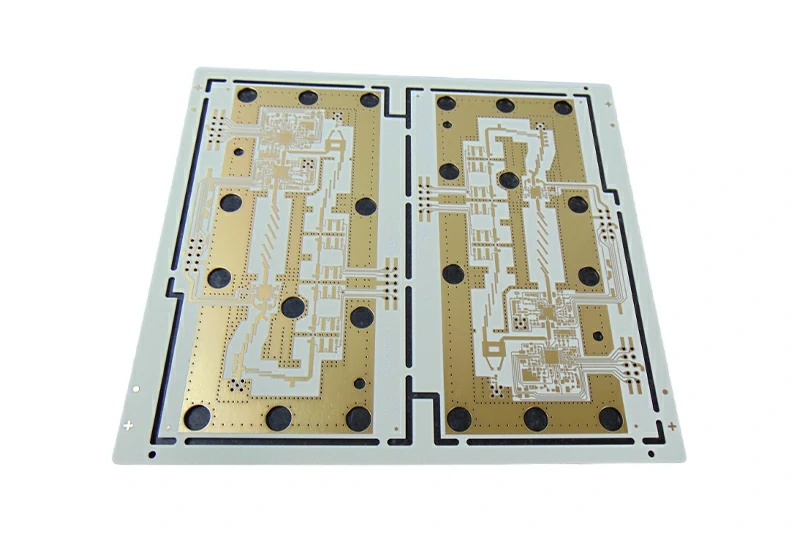

7. High-Frequency and High-Speed PCBs

Definition:

These PCBs are designed to handle high-frequency signals with minimal signal loss or distortion. They often utilize advanced materials with low dielectric constants.

Applications:

Critical in RF communication devices, high-speed computing systems, radar systems, satellite communications, and aerospace electronics.

Advantages:

- Enhanced performance at high frequencies for faster data transmission

- Supports advanced routing techniques like blind/buried vias

Limitations:

- Requires specialized materials and processes, increasing costs

8. Metal Base PCBs

Definition:

Metal-based PCBs utilize a metal substrate—commonly aluminum or copper—to provide superior thermal management capabilities. The metal base acts as a heat sink that dissipates heat effectively.

Applications:

Frequently used in applications requiring efficient heat dissipation, such as LED lighting systems, power electronics, automotive lighting systems, and industrial equipment.

Advantages:

- Excellent thermal conductivity prevents overheating

- Allows for thinner designs without compromising thermal management

Limitations:

- Heavier than traditional options, requiring additional design considerations

Conclusion

Each types of PCB serves distinct purposes based on its construction characteristics and application requirements. A thorough understanding of these differences empowers engineers and designers to select the most suitable PCB type for their projects effectively. At TriWin, we offer an extensive range of PCB solutions tailored to meet diverse needs while ensuring high quality through our certifications. Reach out to us today to discuss how we can assist you with your PCB requirements!