1. Introduction

Silkscreen in PCB design is not merely decorative; it is an essential component that greatly influences the functionality, assembly, and quality of printed circuit boards. This article explores the significance of silkscreen in PCB design, its types, applications, and best practices. Additionally, we introduce TriWin, a professional PCB manufacturer, renowned for its expertise in optimizing silkscreen utilization.

2. Understanding Silkscreen in PCB Design

2.1 What is Silkscreen? v

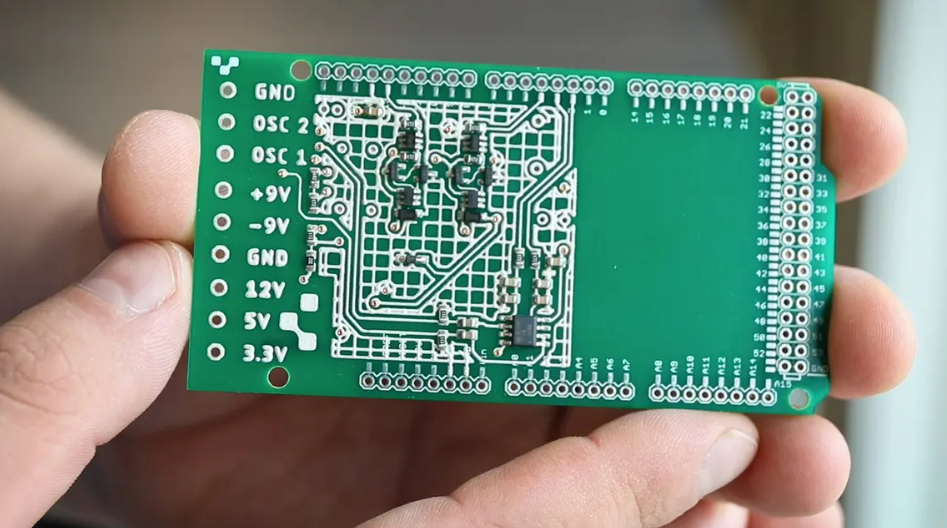

Silkscreen is the layer on a PCB containing text and symbols to help identify components and understand the board layout. Applied after the solder mask, it plays a crucial role in troubleshooting and assembly by providing clear markings and labels, enhancing readability for engineers and technicians.

2.2 Types of Silkscreen Printing Methods

- Manual Screen Printing: A traditional method using a mesh stencil to apply ink by hand. While cost-effective for low-volume production, its accuracy can vary, with an average error rate of up to 10% for high-density boards.

- Liquid Photo Imaging (LPI): This method uses photosensitive ink and UV light exposure for precise silkscreen layers. It is favored for its accuracy (within 0.1mm) and suitability for intricate designs.

- Direct Legend Printing (DLP): DLP uses inkjet printers to directly apply silkscreen onto the PCB. With a resolution of up to 600dpi, it ensures clear, sharp markings and is ideal for high-density boards with complex designs.

3. The Significance of Silkscreen in PCB Design

3.1 Component Identification

Clear silkscreen markings enable quick identification of components, reference designators, and polarity indicators. Research shows that well-marked PCBs reduce assembly time by 30% compared to poorly marked boards.

3.2 Assembly Guidance

Silkscreen provides precise assembly instructions, reducing errors and streamlining processes. For instance, in automotive electronics, silkscreen guidance reduces assembly defects by up to 50%.

3.3 Safety Information

Silkscreen displays warnings, labels, and operational instructions, enhancing safety during usage and maintenance. In medical devices, accurate silkscreen markings ensure correct functionality and reliability.

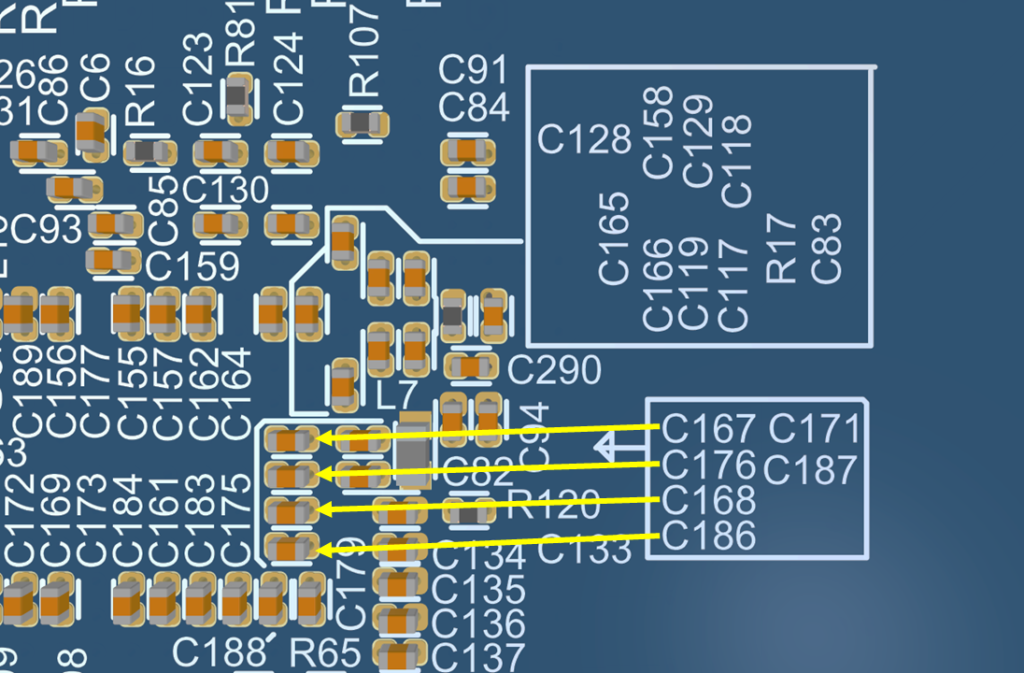

4. Silkscreen Placement and Considerations

4.1 Component Proximity

Silkscreen marks should be close to their respective components without overlapping solder pads or vias. A maximum distance of 1mm is recommended for readability and assembly ease.

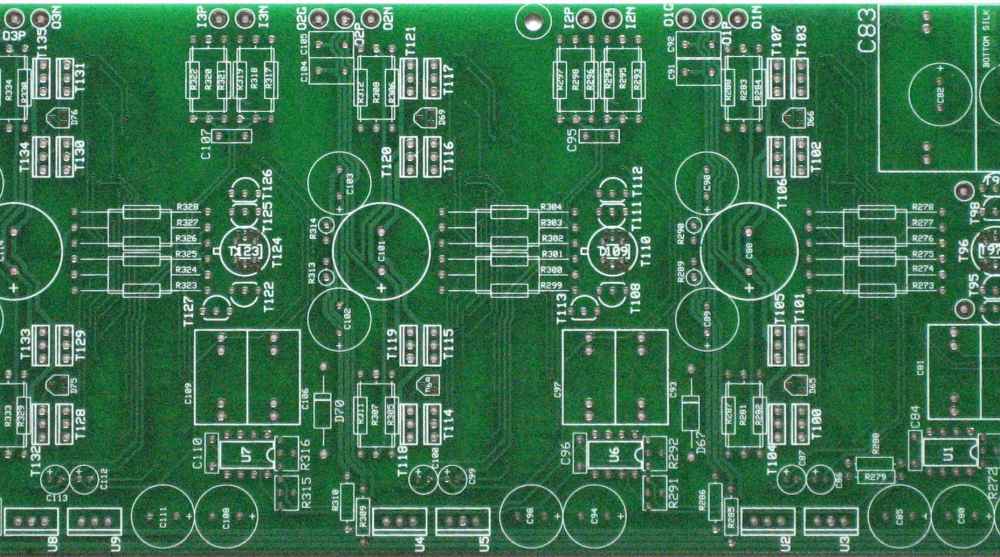

4.2 Layer Selection

While the top layer is standard for silkscreen, the bottom layer can also be utilized, especially in high-density designs. Using both layers maximizes space for markings without compromising other components.

4.3 Font and Text Size

Legible fonts and appropriate text sizes are essential. A font size of 0.8mm or larger is recommended, as smaller fonts increase the error rate in reading silkscreen information by 20%.

5. Silkscreen in High-Density PCBs

5.1 Minimizing Text

Symbols and abbreviations can save space while maintaining readability. This approach has reduced space requirements for silkscreen markings by 40% in aerospace electronics.

5.2 Double-Sided Silkscreen

Utilizing both sides of the PCB alleviates space constraints, enabling comprehensive information without overcrowding the board.

5.3 Prioritization

Essential marks like polarity indicators and component reference designators should be prioritized. Proper prioritization reduces troubleshooting time by 40% in telecommunications applications.

6. Applications of Silkscreen in Various Industries

6.1 Consumer Electronics

In products like laptops and smartphones, silkscreen ensures correct component placement and simplifies troubleshooting, enhancing product quality and customer satisfaction.

6.2 Automotive Electronics

Silkscreen facilitates precise assembly and reliable performance in automotive systems, meeting the industry’s strict reliability standards.

6.3 Medical Devices

Clear silkscreen markings ensure proper operation and reliability of medical equipment, reducing the risk of errors in critical applications.

6.4 Industrial Equipment

In industrial machinery, silkscreen aids in maintenance and troubleshooting, minimizing downtime and ensuring efficient operations.

7. Best Practices for Applying Silkscreen

7.1 Contrast and Color

High-contrast silkscreen colors, such as white, yellow, or black, improve readability by up to 50%, depending on the solder mask.

7.2 Alignment and Registration

Precision alignment ensures accurate placement of silkscreen marks, with advanced techniques achieving an accuracy of within 0.05mm.

7.3 Quality Control

Regular checks detect legibility issues early, reducing errors and saving costs. Strict quality control measures have reduced rework and scrap rates by 60% in the electronics manufacturing industry.

8. TriWin: Your PCB Manufacturing Ally

TriWin, established in 2015 in Huizhou, Guangdong, China, operates a 10,000-square-meter factory with over 220 skilled professionals. With an annual capacity of 250,000 square meters and certifications including ISO9001, IATF16949, ISO14001, and UL, TriWin excels in PCB production.

We specialize in a wide range of high-quality PCBs, from single/double-sided to multilayer (HDI), flexible, flex-rigid, high-frequency, high-speed, metal base, and thermoelectric separation copper base (SinkPAD) PCBs. Our expertise in silkscreen technology ensures sharp, durable markings that enhance PCB reliability and performance.

In conclusion, silkscreen is a vital aspect of PCB design. Partnering with TriWin ensures high-quality PCBs with superior silkscreen, elevating the reliability and performance of your electronics.