Choosing the right circuit protection for your electronic device can mean the difference between a reliable product and one prone to catastrophic failure. Among the many protective components available, the PCB fuse is a reliable and effective solution for safeguarding circuits against damage caused by sudden surges, short circuits, or other sources of overcurrent. In this article, we explore the basics of PCB fuses, discuss their various types, and offer guidance for selecting, installing, and maintaining them effectively.

Understanding PCB Fuses

A PCB fuse performs much like a conventional fuse: it breaks—or “opens”—when the current passing through it exceeds the specified limit. By interrupting the current flow, the fuse helps prevent significant and potentially irreparable damage to electronic components. PCB fuses are designed to be mounted directly onto a printed circuit board (PCB), thus saving space and simplifying the assembly process.

Fundamentally, fuses use a metallic element that acts as a weak link. When a current higher than the fuse’s rating passes through, the element melts due to excessive heat, thereby cutting off power to the rest of the circuit. This fundamental principle underpins the role of PCB fuses in various products, from small consumer gadgets to industrial equipment.

How PCB Fuses Prevent Damage

- They respond quickly to overcurrent events.

- They help isolate specific parts of the circuit.

- Once tripped (melted), they must typically be replaced, ensuring that damaged sections are assessed before being returned to operation.

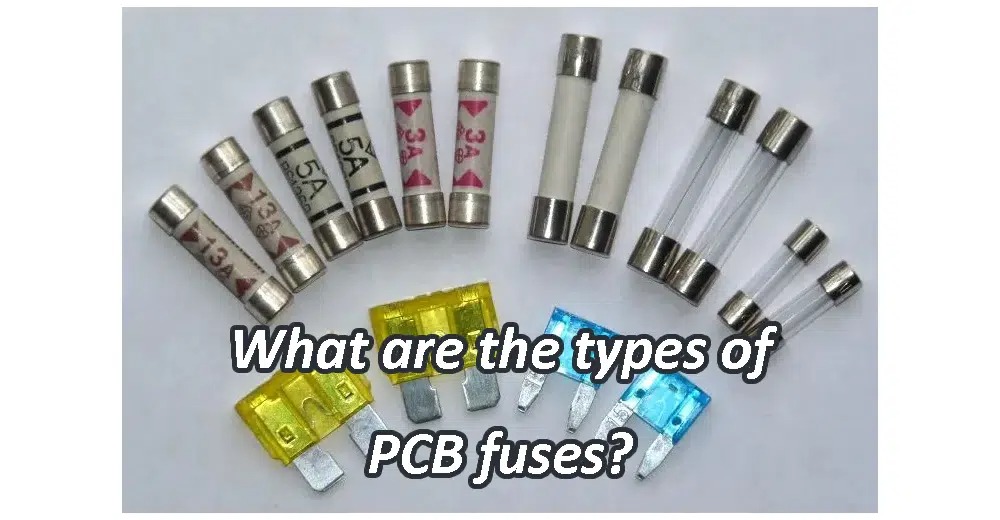

Different Types of PCB Fuses

The importance of selecting the correct fuse type for your specific application cannot be understated—each type has unique benefits, cost considerations, and best-use scenarios.

SMD (Surface Mount) Fuses

These compact fuses attach directly to the surface of the PCB. They tend to be very small and lightweight, making them ideal for high-density PCBs where space is at a premium. They can be easily placed using automated pick-and-place technology, helping reduce production time and cost.

Through-Hole Fuses

Though more traditional, through-hole fuses continue to see widespread use in circuits that demand higher durability or want to accommodate easy fuse replacement. They are mounted through drilled holes in the PCB, providing a mechanically robust connection. Because these fuses protrude from the board, they may not be the best solution where compact size is crucial.

PTC Resettable Fuses (Polymeric Fuses)

Also known as Positive Temperature Coefficient (PTC) fuses, these act somewhat differently from traditional fuses. In an overcurrent event, they increase their resistance dramatically, effectively limiting current flow, but they do not always blow permanently. After the fault is cleared and the temperature returns to normal, they can reset, restoring current flow. This is especially advantageous in applications requiring automatic recovery without physically replacing the fuse.

Specialized Fuses (High-Voltage Fuses)

For circuits that operate at higher voltages or require additional surge protection, specialized high-voltage fuses are designed to interrupt currents safely under more extreme conditions. They often incorporate specific design features, like arc-quenching materials, to handle risky high-energy events.

Key Components and Manufacturing of PCB Fuses

PCB fuses typically use conductive materials such as zinc, copper, or silver in their fuse elements. The chosen material must withstand normal operating current without generating excessive heat. Moreover, fuse bodies can feature ceramic, glass, or other insulating materials to protect against short-circuit events. Manufacturing processes emphasize precision so that each fuse meets strict performance specifications.

- Current Rating: The maximum continuous current that the fuse can handle without blowing.

- Voltage Rating: The effective level of voltage at which the fuse can safely operate—even after a fault occurs.

- Time-Current Characteristic: Fuses can be fast-blow (respond quickly to minor overcurrent events) or slow-blow (allow transient spikes but open if the overcurrent persists).

Importance of PCB Fuses in Different Industries

Consumer Electronics

Devices such as smartphones, tablets, wearables, or gaming consoles rely on PCB fuses as a first line of defense. A burn or meltdown in one circuit area can generate costly returns or warranty claims, so having the right fuse in place safeguards not just the product but also consumer satisfaction.

Automotive Sector

Automobiles depend on many sophisticated electronics, from entertainment systems to advanced driver-assistance systems (ADAS). PCB fuses in automobiles must survive vibrations, temperature extremes, and voltage fluctuations. Consequently, automotive fuses often meet stringent quality standards like IATF16949.

Industrial and Heavy Machinery

Industrial settings frequently encounter unpredictable power surges and large-scale electrical loads. In these environments, a robust PCB fuse tailored to manage high current levels is essential. Without effective protection, machinery downtime and expensive repairs become far more likely.

Medical Devices

Surgical instruments, patient monitoring systems, and other healthcare devices cannot afford preventable malfunctions. Incorporating reliable PCB fuses supports the industry’s strict safety and reliability requirements, reducing the possibility of accidental harm to patients.

Considerations for Selecting a PCB Fuse

Choosing an appropriate PCB fuse involves aligning the device’s operating conditions with fuse ratings:

- Overcurrent Rating and Short-Circuit Protection: Ensure that normal operating currents stay below the fuse rating, but that the fuse will open quickly when an overcurrent event occurs.

- Voltage Requirements and Temperature Tolerance: Verify that the fuse can handle the voltage levels and environmental conditions of your specific application.

- Certifications and Safety Standards: Look for fuses that meet standards such as UL, CSA, or IEC. In automotive or medical contexts, additional certifications may be required.

- Data Sheet Analysis and Performance Metrics: Compare nominal blow times, interrupting ratings, and other critical parameters to find the right match.

Installation and Best Practices

Correct installation is just as crucial as proper fuse selection. During assembly, follow the manufacturer’s soldering guidelines to avoid degrading the fuse element. Place fuses in easily accessible parts of the PCB, making them more straightforward to replace if a fault occurs. Additionally, thorough testing, both before and after final assembly, ensures large batches of finished products start their lifecycle with minimal risk of fuse-related failures.

Common Misconceptions About PCB Fuses

Despite their well-understood operation, several misconceptions persist:

- Fuse vs. Circuit Breaker: While people sometimes see fuses and breakers as interchangeable, they serve different use cases. Fuses are especially inexpensive, compact, and well-suited for PCB-level protection, whereas breakers are typically used at higher power levels and are reusable.

- Fuse Overrating: Some engineers assume using a higher-rated fuse is safer, but doing so can defeat the purpose, allowing too much current to pass before blowing.

- Lifespan and Reliability: A fuse does not “wear out” unless a fault or near-fault condition arises repeatedly. Each product has its own specification for cumulative on/off cycles and surge tolerance.

Final Summary & Next Steps

PCB fuses offer a simple yet effective means of protecting electronics, ranging from consumer gadgets to industrial equipment. By providing overcurrent protection at the board level, these fuses prevent the spread of damage throughout a system. Knowing how to select the right fuse, ensuring proper installation, and understanding their role in circuit protection can significantly reduce the risk of malfunctions and costly repairs down the road.

At TriWin, we specialize in manufacturing a wide variety of PCBs, from single-layer and double-sided boards to advanced HDI and metal-based solutions. With our years of experience, we recognize the critical role that protective components—like PCB fuses—play in reliable circuit performance. Our engineering team is well-versed in working alongside clients to ensure design for manufacturability (DFM) and can guide you in choosing the best protective measures for your board. If you’re looking for a dependable partner with certifications like ISO9001, IATF16949, ISO14001, and UL, TriWin is here to help you navigate the complex process of PCB production and assembly. We look forward to supporting your next project, from initial design considerations to final product rollout, with a focus on safety, efficiency, and quality.