Metal Core PCBs (MCPCBs) are revolutionizing the electronics industry by addressing one of the most critical challenges in modern electronic devices: thermal management. As electronic components become more powerful and compact, the need for efficient heat dissipation has never been greater. MCPCBs, with their unique construction and superior thermal properties, provide an effective solution to this problem.

In this article, we will explore the world of Metal Core PCBs, delving into their construction, advantages, applications, and manufacturing considerations. Whether you are an engineer, designer, or business owner, this guide will equip you with the knowledge to make informed decisions about incorporating MCPCBs into your projects. Let’s dive in and discover how MCPCBs can enhance the performance and reliability of your electronic devices.

Understanding Metal Core PCBs

Metal Core PCBs (MCPCBs) are a specialized type of printed circuit board that incorporate a metal core, typically made of aluminum, copper, or stainless steel, as part of their structure. This metal core serves as a heat sink, efficiently dissipating heat away from critical components and ensuring the stability and longevity of the electronic device.

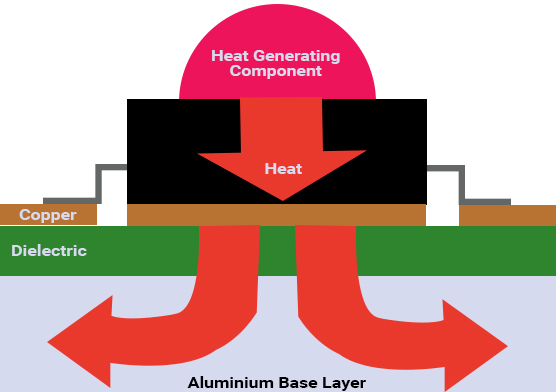

The construction of an MCPCB typically includes three main layers:

- Metal Core Layer: The base layer, made of metal, provides excellent thermal conductivity and mechanical strength.

- Insulation Layer: A thermally conductive but electrically insulating layer separates the metal core from the copper circuitry.

- Copper Circuit Layer: The top layer, where the electronic components are mounted, allows for electrical connections and signal transmission.

Compared to traditional FR4 PCBs, MCPCBs offer significantly better thermal performance. While FR4 PCBs rely on thermal vias and external heat sinks to manage heat, MCPCBs integrate the heat dissipation mechanism directly into their structure. This makes them ideal for applications where heat management is critical, such as high-power LEDs and power electronics.

By understanding the unique construction and properties of MCPCBs, engineers and designers can leverage their advantages to create more reliable and efficient electronic devices.

Key Advantages of Metal Core PCBs

Metal Core PCBs offer a range of benefits that make them indispensable in applications requiring efficient thermal management and durability. Here are the key advantages:

Superior Thermal Conductivity

The metal core in MCPCBs acts as an integrated heat sink, efficiently transferring heat away from heat-generating components. This reduces the risk of overheating and ensures stable performance, even in high-power applications. Compared to traditional FR4 PCBs, MCPCBs can handle significantly higher thermal loads, making them ideal for LED lighting and power electronics.

Enhanced Mechanical Strength

The metal base provides added mechanical stability, allowing MCPCBs to withstand physical stress and temperature fluctuations. This durability is particularly important in automotive and industrial applications where reliability is critical.

Better Thermal Expansion Matching

The metal core helps to match the thermal expansion coefficients of the PCB and its components, reducing the risk of delamination or component failure due to temperature changes. This ensures long-term reliability and performance.

By leveraging these advantages, Metal Core PCBs enable the development of high-performance, reliable electronic devices that can operate efficiently in demanding environments.

Applications of Metal Core PCBs

Metal Core PCBs are widely used in industries where efficient heat dissipation and reliability are paramount. Here are some key applications:

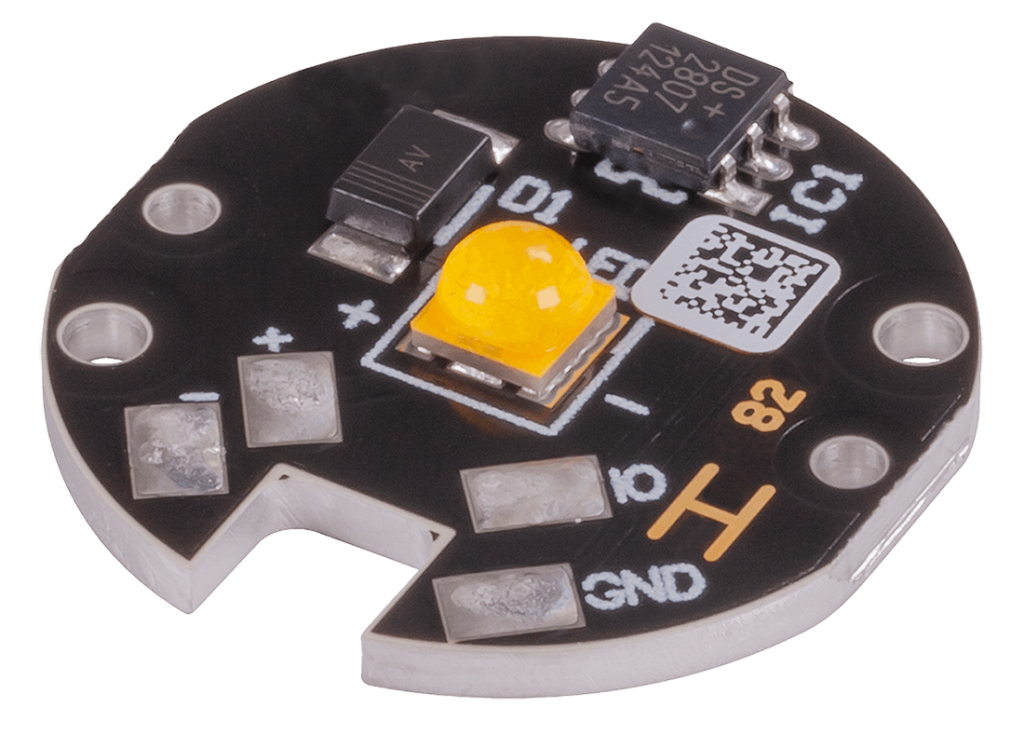

LED Lighting

MCPCBs are the backbone of high-power LED lighting systems. Their superior thermal conductivity ensures that heat generated by LEDs is effectively dissipated, enhancing the lifespan and performance of the lighting system. Common applications include street lighting, automotive headlights, and indoor and outdoor LED displays.

Power Electronics

In power converters, inverters, and motor drives, MCPCBs play a crucial role in managing heat generated by high-power components. This ensures stable operation and prevents overheating.

Automotive Electronics

Automotive systems such as engine control units, safety systems, and lighting rely on MCPCBs for their ability to withstand harsh operating conditions and manage heat effectively.

Renewable Energy Systems

MCPCBs are used in solar panels and photovoltaic cells to manage heat and improve energy efficiency. Their durability and thermal performance make them ideal for renewable energy applications.

By understanding the diverse applications of Metal Core PCBs, businesses can identify opportunities to enhance the performance and reliability of their products.

Manufacturing Considerations for Metal Core PCBs

Producing Metal Core PCBs requires specialized processes and expertise to ensure high quality and performance. Here are some key considerations:

Manufacturing Process

The production of MCPCBs involves precise layering of the metal core, insulation layer, and copper circuitry. Advanced techniques are used to ensure strong adhesion and thermal conductivity between layers. Drilling and routing processes must account for the hardness of the metal core, requiring specialized equipment and tools.

Challenges

Compared to standard FR4 PCBs, MCPCBs present unique challenges such as managing thermal expansion and ensuring uniform heat dissipation across the board. The selection of materials—including the type of metal core and insulation layer—is critical to achieving desired thermal and mechanical properties.

Quality Certifications

To ensure reliability and compliance with industry standards, manufacturers must adhere to certifications such as ISO9001, IATF16949, ISO14001. These certifications demonstrate a commitment to quality and environmental responsibility.

By understanding these manufacturing considerations, businesses can select a trusted partner with the expertise and capabilities to deliver high-quality Metal Core PCBs.

TriWin PCB: Your Trusted Partner for Metal Core PCBs

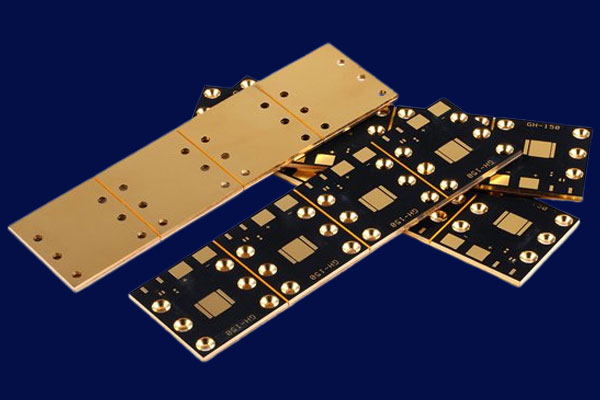

At TriWin PCB, we pride ourselves on being a professional manufacturer of high-quality Metal Core PCBs. Established in 2015 and located in HuiZhou city, GuangDong province, China, our factory spans an area of about 10,000 square meters equipped with state-of-the-art facilities.

With a team of over 220 experienced experts, engineers, and technicians, we have the expertise to produce a wide range of PCBs including aluminum base, copper base, and thermoelectric separation copper base PCBs (SinkPAD PCBs). Since 2017 we have been specializing in the development and mass production of Metal Core PCBs ensuring mature manufacturing processes.

Our annual production capacity of approximately 250,000 square meters is backed by certifications such as ISO9001, IATF16949, ISO14001, and UL reflecting our commitment to quality and environmental responsibility. Whether you need MCPCBs for LED lighting, power electronics, automotive systems, or renewable energy applications—TriWin PCB is your trusted partner for innovative solutions.

Choose TriWin PCB for your Metal Core PCB needs today! Experience the difference in quality performance along with exceptional customer service that sets us apart from competitors.

Conclusion

Metal Core PCBs are a game-changer in the electronics industry, offering unparalleled thermal management, mechanical strength, and reliability. From LED lighting to power electronics, automotive systems, and renewable energy applications—MCPCBs enable the development of high-performance, durable electronic devices.

At TriWin PCB, we are committed to providing top-quality Metal Core PCBs that meet the highest industry standards. With our advanced manufacturing capabilities, experienced team, and dedication to customer satisfaction—we are your ideal partner for all your MCPCB needs.