I’ve seen people struggle with flexible PCBs. It’s tough when a board snaps or fails to bend right. You’re probably wondering how much a PCB can flex. Let’s figure it out together.

A PCB can flex depending on its type. Flexible PCBs bend up to 180 degrees, while rigid-flex boards handle less—about 20-30 degrees—before damage.

I’ve had projects where flexibility was key. One wrong move, and it’s game over. Stick with me, and I’ll share what I’ve learned.

Table of Contents

- What Makes a PCB Flexible?

- How Much Can Flexible PCBs Bend?

- What Limits PCB Flexibility?

- Can Rigid-Flex PCBs Bend Too?

- How Do I Test PCB Flexibility?

- Conclusion

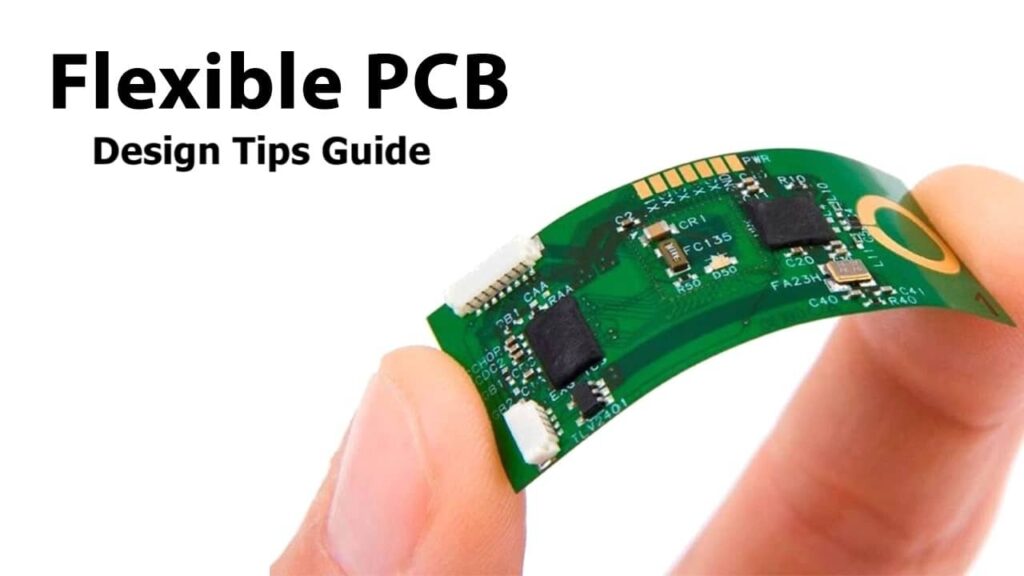

What Makes a PCB Flexible?

I get asked this all the time at work. Not every PCB bends. It’s about design and materials. Let’s break it down.

Flexible PCBs use polyimide or polyester films with thin copper layers. These materials let the board bend without breaking.

Dive Deeper: The Building Blocks

I’ve worked with these boards for years. Flexibility comes from a few key things.

Materials

I use polyimide because it’s tough and bends well. Polyester works too, but it’s less durable.

Copper Thickness

Thinner copper flexes better. I stick to 0.5 oz or 1 oz for flexible designs.

Layers

Single-layer boards bend most. I’ve seen multi-layer ones flex, but they’re stiffer.

It’s simple. I pick the right mix for the job.

How Much Can Flexible PCBs Bend?

I’ve seen clients push boards to their limits. How far can they go? Let’s find out.

Flexible PCBs can bend up to 180 degrees or more, depending on thickness and radius. Some handle tight curves down to 1 mm.

Dive Deeper: Measuring the Bend

I’ve tested this in production. Here’s what matters.

Bend Radius

I aim for a radius 10 times the board’s thickness. A 0.1 mm board bends to 1 mm.

Thickness

Thinner is better. I’ve flexed 0.05 mm boards into loops without cracks.

| Thickness (mm) | Min Bend Radius (mm) | Max Angle |

|---|---|---|

| 0.05 | 0.5 | 180°+ |

| 0.1 | 1.0 | 180° |

| 0.2 | 2.0 | 90-120° |

I keep it safe. Too tight, and the copper splits.

What Limits PCB Flexibility?

I’ve had boards fail because of this. Flexibility has boundaries. Let’s see what holds it back.

PCB flexibility is limited by copper thickness, adhesive strength, and component placement. Thick copper and heavy parts reduce bending.

Dive Deeper: The Constraints

I’ve learned this the hard way.

Copper Thickness

Thicker copper resists bending. I avoid 2 oz for flex boards—it’s too stiff.

Adhesive

Weak glue peels apart. I use strong adhesives to keep layers tight.

Components

Big parts limit flex. I place them where the board stays flat.

| Factor | Impact on Flex | My Fix |

|---|---|---|

| Copper (2 oz) | Lowers bend ability | Use 0.5-1 oz |

| Weak Adhesive | Layers separate | Stronger bonding |

| Heavy Components | Restricts movement | Strategic placement |

I design around these. It’s all about planning.

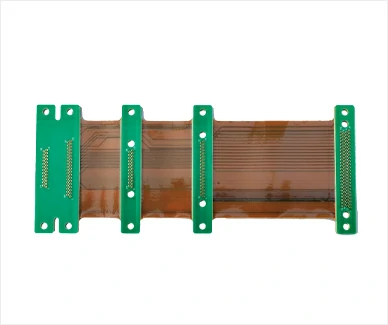

Can Rigid-Flex PCBs Bend Too?

I’ve worked with rigid-flex boards a lot. They’re tricky. How much can they flex? Let’s check.

Rigid-flex PCBs bend less—about 20-30 degrees in flex zones. Rigid parts don’t flex, but the flexible sections connect them.

Dive Deeper: Rigid vs. Flex

I’ve seen these in action. Here’s the deal.

Flex Zones

I keep bends in the flexible parts. They handle 20-30 degrees safely.

Rigid Sections

These don’t move. I use them for stability and mounting.

Transition Areas

I reinforce these spots. They crack if bent too hard.

| Type | Flex Range | Best Use |

|---|---|---|

| Flexible | 180°+ | Full bending needs |

| Rigid-Flex | 20-30° | Mixed stability |

I pick rigid-flex when I need both strength and some bend.

How Do I Test PCB Flexibility?

I’ve ruined boards by guessing. Testing is key. How do I do it? Let’s look.

Test PCB flexibility with bend radius tools or manual flexing. Measure angles and check for cracks or resistance.

Dive Deeper: My Testing Process

I’ve got a system that works.

Tools

I use a bend tester. It measures radius and stress points.

Manual Check

I flex by hand to feel resistance. If it fights back, it’s too stiff.

Inspection

I look for cracks with a magnifying glass. Copper splits show limits.

| Test Method | What I Check | Result |

|---|---|---|

| Bend Tester | Radius, stress | Exact flex limit |

| Manual Flex | Resistance | Quick feel test |

| Visual Check | Cracks, splits | Confirms durability |

I test every batch. It saves me from failures.

Conclusion

I’ve shared how much a PCB can flex. Flexible boards go up to 180 degrees with thin copper and smart design. Rigid-flex tops out at 30 degrees in flex zones. Limits come from thickness, glue, and parts. Test it right, and you’re set. At TriWin PCB, we’ve been building flexible and rigid-flex boards since 2015. We’re here to make your project work.