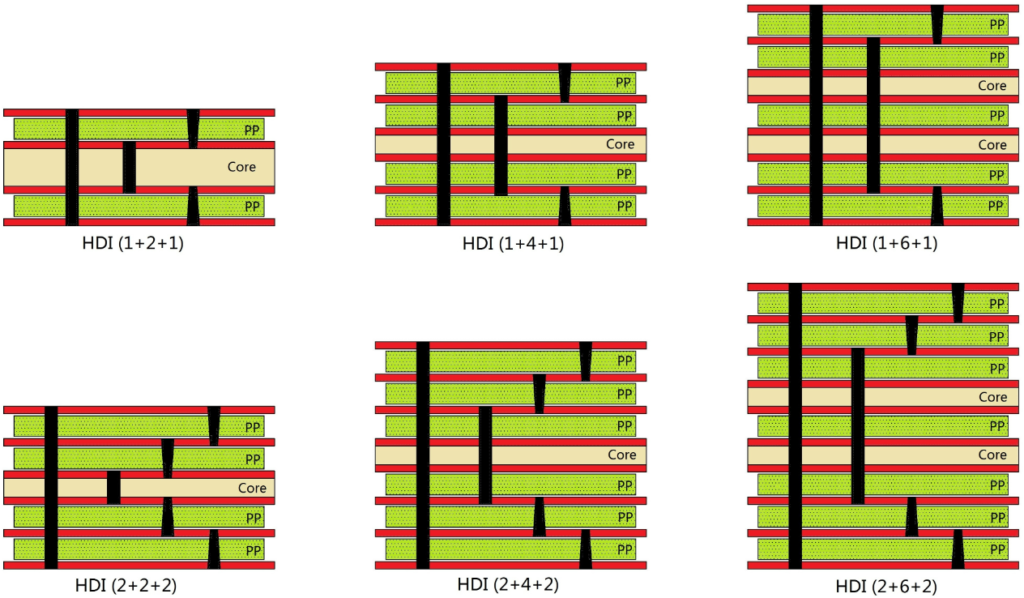

HDI (High Density Interconnect) is a high density interconnect technology that enables more tracks and interconnect through holes. Compared to traditional circuit boards, HDI technology can achieve more functions in a smaller size.

| Layers: | 6 Layers |

| Material: | FR4 TG170 |

| Finish board thickness: | 1.6mm |

| Finish copper thickness: | 1 oz |

| Surface treatment: | ENIG |

| Solder mask: | Green |

| Notes: | UL/ISO/IATF16949/SGS certification, Halogen free |

HDI (High Density Interconnect) is a high density interconnect technology that enables more tracks and interconnect through holes. Compared to traditional circuit boards, HDI technology can achieve more functions in a smaller size.

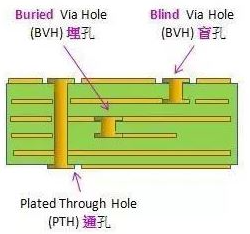

HDI technology mainly realizes high density interconnection through the following aspects: First, through the design of micro-tracks and holes, more tracks can be realized in a limited space; Secondly, using blind hole and buried hole technology, electrical connection between different layers can be realized, thus reducing the layer spacing; In addition, the stackup of micro-lines and inner layer crossing of tracks are also used to further improve the line density and interconnection performance.

1.High density: The biggest feature of HDI board is high density. Compared to traditional printed circuit board (PCB),HDI boards have a smaller line width/space, allowing for higher component density. This not only helps to reduce the volume and weight of the product, but also improves the performance and reliability of the product.

2.Small size: Due to the high-density nature of the HDI board, it can achieve a smaller size while maintaining high performance. This is especially important for high-end electronics that need to integrate more functions into a limited space, such as smartphones, tablets and wearables.

3.High-speed signal transmission: The HDI board uses a fine line design, which can achieve high-speed and stable signal transmission. This is critical for high-end electronics that need to process large amounts of data in real time, such as data centers, cloud computing, and artificial intelligence devices.

4.Strong anti-interference ability: the high-frequency characteristics of the HDI board make it have strong anti-interference ability, which can effectively reduce the impact of electromagnetic interference on product performance. This is especially important for high-end electronics that work in complex environments, such as aerospace, military, and medical devices.

5.Environmental protection and energy saving: HDI board uses environmentally friendly materials and processes, which can reduce the energy consumption and emissions of the product.

HDI technology is widely used in computer, mobile communication, medical equipment, automotive electronics, military, Internet of Things (LoT) and other fields, providing possibilities for miniaturized and high-performance electronic products.

Please send us your PCB data (include gerber and specs), and quantity you need, as well as the mode of delivery, we will provide price to you ASAP, our Email address please see “Contact us”page.

Please send us your PCB data (include gerber and specs), together with your purchase order (PO),our Email address please see “Contact us”page, we will provide EQ (engineering query) (if have) to you ASAP, after all engineering questions are solved, we will start production and ship to you within your required delivery date.

Trace width/space: 0.075/0.075mm min., 0.1/0.1mm generally for 1 oz copper. Via size: 0.15mm mechanical drill, Board thickness: 0.4mm for rigid PCBs.

Yes, we are professional Aluminum base PCB supplier, we also produce Copper base PCB, FR4 PCB, such as double sides, multilayer, HDI, Flex-rigid, Flex, and so on.

Yes, we could panelized your different single PCBs together in one panel when production, and rout panel into individual PCBs before delivery.

RS 274x format is the best and most common gerber format, of course, files designed by PROTEL99SE, Altium Designer, PADS are also OK for us.

Generally speaking, 2-3 working days for sample, 6-7working days for mass production. Of course, delivery date concerned with the level of difficulty, such as layers and PCB type, more process need more time.

ENIG (Immersion gold), Selective hard gold, HASL lead free, OSP, Immersion tin, Immersion silver, ENEPIG, etc.

S1141, S1000H, S1000-2, S1155, S1165, KB6060, KB6165, IT158C, IT180A, 370HR, VT-47, FR408、FR408HR、IS410、FR406, EM827, TU 752, Rogers 4003, Rogers 4350, etc.

If your PCB need other special brand material, we could manage to purchase it for you.

Your Trusted Partner for Reliable PCB Solutions.

Copyright © 2024, TriWin P.C.B. Co.,Ltd All rights reserved