As a leading provider of high-quality PCB fabrication and assembly, we at Tri-Win Circuits often get the question: “How much will it cost to fabricate my PCB?” It’s the most fundamental question for any electronics project, yet the answer is rarely a simple number. The price of a printed circuit board is not a fixed commodity; it’s a result of a complex interplay of design choices, material selection, and manufacturing processes.

Instead of giving you a vague “it depends,” this article will break down the precise factors that influence your PCB fabrication costs. We’ll equip you with the knowledge to understand your quote, make cost-effective design decisions, and partner with a manufacturer who provides true value. Let’s peel back the layers on PCB pricing.

Article Contents

- How Much Does It Really Cost to Fabricate a PCB?

- What Core Factors Determine PCB Fabrication Costs?

- Are There Ways to Make My PCB Project More Affordable?

- What’s the Price Difference Between Prototype and Mass Production PCBs?

- Why Does Your Choice of a PCB Fabricator Matter for Pricing?

- Ready to Get an Accurate Price for Your PCB?

How Much Does It Really Cost to Fabricate a PCB?

The cost of manufacturing a single PCB can range from a few dollars for a simple, standard-spec prototype to several thousand dollars for a highly complex, multi-layer rigid-flex board with specialized materials. The primary driver of this range is complexity and quantity. A simple 2-layer board ordered in a batch of 10,000 might cost less than $1 per board. In contrast, a single 12-layer HDI prototype with blind and buried vias could cost well over $1,000 for that one unit.

This variability is why instant online calculators provide an estimate, but a detailed quote from a manufacturing partner like Tri-Win Circuits is essential for accurate budgeting. The initial quote you receive is based on the specific data in your Gerber files and the manufacturing requirements you select. Understanding these requirements is the first step to controlling your costs.

What Core Factors Determine PCB Fabrication Costs?

Your final PCB cost is a sum of its parts—literally. Every choice you make in your design software has a direct impact on the materials, processes, and labor required for fabrication. We can group these cost drivers into four main categories.

1. The Fundamental Board Specifications

These are the most significant cost drivers and are determined at the earliest stages of your design. The larger and more layered your board, the more material and processing time it requires.

| Factor | Description | Cost Impact |

|---|---|---|

| Board Size (Dimensions) | The length and width of the PCB. Larger boards consume more base material (laminate). | High. Cost increases directly with area. |

| Number of Layers | The count of conductive copper layers. Standard is 2, but can go to 40+. | Very High. Each additional layer requires more lamination and drilling steps, significantly increasing complexity and cost. |

| Material Type | The base substrate. Standard FR-4 is most common and cost-effective. High-frequency materials like Rogers or specialized substrates like Aluminum for thermal management are more expensive. | High. Specialized materials can cost 5-20 times more than standard FR-4. |

| Board Thickness | The overall thickness of the PCB. Standard thicknesses (e.g., 1.6mm) are cheaper. Custom thicknesses may require special material stock. | Moderate. Non-standard thicknesses can add to the cost. |

| Copper Weight | The thickness of the copper foil on each layer. Standard is 1 oz (35µm). Heavy copper (2 oz+) costs more due to raw material and etching challenges. | Moderate to High. Heavy copper significantly increases material and processing costs. |

2. Technical Complexity and Precision

Beyond the basics, the intricacy of your design plays a crucial role. Tighter tolerances and advanced features require more sophisticated equipment, slower production speeds, and higher quality control, all of which add to the cost.

- Minimum Trace and Space: The smaller the gap between conductive traces and the thinner the traces themselves, the more advanced the imaging and etching processes must be. Standard spacing (e.g., >= 5 mil) is cheaper than ultra-fine lines (e.g., 3 mil).

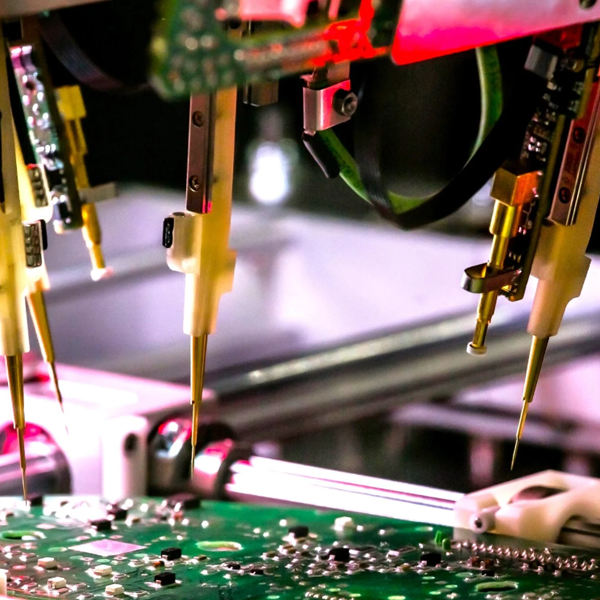

- Hole Size and Density: Smaller drill holes (microvias) require laser drilling instead of mechanical drilling, which is more expensive. A higher number of holes per square inch also increases machine time and cost.

- Via Technology: Standard “through-hole” vias are the cheapest. More complex structures like blind vias (connecting an outer layer to an inner one) and buried vias (connecting two inner layers) require multiple lamination and drilling cycles, drastically increasing the price.

- Controlled Impedance: If your design requires specific impedance values for high-speed signals, it necessitates tighter manufacturing tolerances and additional testing (TDR), which adds to the cost.

3. Finishing and Customization Options

These final touches protect the board and aid in assembly. While some are standard, certain choices can influence the final price.

- Surface Finish: This coating protects the copper pads from oxidation. Standard HASL (Hot Air Solder Leveling) is the most cost-effective. Premium finishes like ENIG (Electroless Nickel Immersion Gold), while offering a flatter surface and longer shelf life, are more expensive due to the cost of gold and the complex chemical process.

- Solder Mask Color: Green is the industry standard and almost always the cheapest option. Other colors like black, red, blue, or white may carry a small premium.

- Silkscreen: A single-sided silkscreen in a standard color (white) is usually included. Adding a second side or using non-standard colors can add minor costs.

4. Logistics and Volume

Finally, how and when you order your boards has a massive impact on the per-unit price.

- Quantity: This is one of the most significant factors. PCB manufacturing involves fixed setup costs (tooling, NRE). For a small prototype run, these setup costs are spread over just a few boards, making the per-unit price high. For a large production run, the setup cost is spread over thousands of units, dramatically lowering the per-unit price.

- Turnaround Time: “Time is money” is especially true in PCB fabrication. Standard lead times (e.g., 1-2 weeks) are the most economical. Expedited or quick-turn services (e.g., 24-48 hours) require shuffling production schedules and running dedicated lines, which carries a significant premium.

Are There Ways to Make My PCB Project More Affordable?

Absolutely. As your manufacturing partner, we want to help you achieve the perfect balance of performance and price. Here are several expert strategies to reduce your PCB fabrication costs without sacrificing quality:

- Stick to Standard Specs: Whenever possible, design with standard board thicknesses (1.6mm), copper weights (1 oz), and trace/space clearances (e.g., 6/6 mil). Deviating from the norm often adds cost.

- Optimize Your Board Size: Keep your board as small as your components will allow. Also, consider designing in a way that allows for efficient panelization, where multiple copies of your board are fabricated on a single larger panel to minimize material waste.

- Minimize Layer Count: Before moving from a 2-layer to a 4-layer design, exhaust all layout possibilities. An extra day spent on clever routing is far cheaper than doubling your layer count.

- Plan Ahead: Avoid paying expedite fees. By planning your project timeline to allow for standard manufacturing lead times, you can achieve the lowest possible cost.

- Get a DFM Check: A Design for Manufacturability (DFM) review, a service we provide at Tri-Win Circuits, can identify costly or difficult-to-produce features in your design before production begins, allowing you to make cost-saving adjustments.

What’s the Price Difference Between Prototype and Mass Production PCBs?

The journey from a prototype to a full production run involves a significant shift in pricing strategy, primarily due to Non-Recurring Engineering (NRE) costs and economies of scale.

NRE costs are the one-time setup fees for creating the tools and programming needed to manufacture your specific board. This includes creating the photoplots, setting up drill and route programs, and building any required electrical test fixtures. For a 10-piece prototype run, this NRE cost is the bulk of your bill. For a 10,000-piece production run, that same NRE cost becomes a negligible fraction of the total order. This is why the per-board price plummets as quantity increases.

At Tri-Win Circuits, we specialize in supporting projects from High-Mix, Low-Volume (HMLV) prototypes to full-scale production. We understand the cost pressures at the prototyping stage and work with our clients to ensure a smooth and cost-effective transition to mass manufacturing.

Why Does Your Choice of a PCB Fabricator Matter for Pricing?

Choosing the cheapest upfront quote isn’t always the most cost-effective decision. The right manufacturing partner provides value that extends far beyond the initial price tag. A partner like Tri-Win Circuits saves you money in the long run by preventing costly errors and delays.

- Quality and Reliability: A board that fails in the field due to poor fabrication costs far more in recalls and reputation damage than the few dollars saved on a cheap quote. Our adherence to stringent quality standards (ISO 9001, UL) ensures your boards work correctly the first time.

- Expertise and DFM Support: Our engineering team can spot potential manufacturing issues in your design, saving you from a costly and time-consuming board respin. This proactive support is invaluable.

- One-Stop Solution: By offering both PCB fabrication and assembly, we provide a seamless, integrated process. This eliminates the logistical headaches and potential for error that come from managing two separate vendors, saving you time, money, and stress.

- Transparent Quoting: We provide clear, itemized quotes that help you understand exactly what you’re paying for. There are no hidden fees—just a clear partnership aimed at bringing your design to life efficiently and effectively.

Ready to Get an Accurate Price for Your PCB?

Understanding the factors that influence PCB fabrication cost empowers you to design more efficiently and budget more effectively. While this guide provides a comprehensive overview, the only way to know the exact cost for your unique design is to get a formal quote.

The team at Tri-Win Circuits is ready to help. We combine advanced technology with a commitment to customer success, ensuring you get a high-quality product at a fair and transparent price. Contact us today to submit your Gerber files and receive a detailed, no-obligation quote for your next project.