Choosing PCB copper thickness can feel overwhelming. I’ve seen projects fail because of bad choices. It’s a big deal, and I want to help you get it right.

You choose PCB copper thickness based on current load, heat needs, and board size. Thicker copper handles more power, while thinner suits small designs.

I’ve worked on boards that overheated once. It was a mess! Let’s dive in and make this simple for you.

Table of Contents

- Why Does Copper Thickness Matter in PCBs?

- What Are Standard PCB Copper Thickness Options?

- How Does Current Load Affect Copper Thickness?

- Can Copper Thickness Impact Heat Management?

- How Do Cost and Size Influence Copper Thickness?

- Conclusion

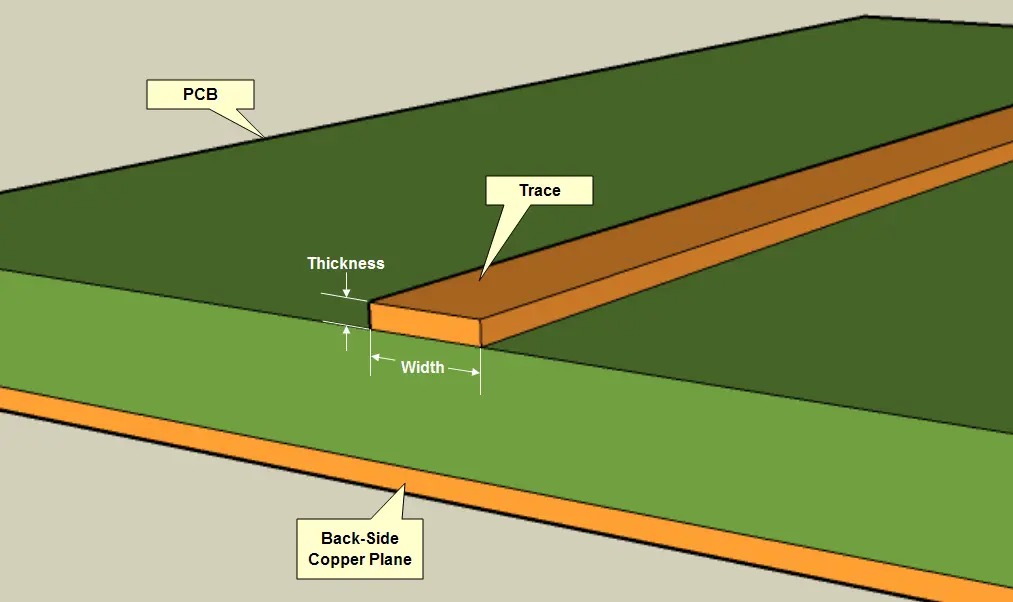

Why Does Copper Thickness Matter in PCBs?

I get this question a lot at work. Copper thickness isn’t just a number—it shapes how your board performs. Let’s break it down.

Copper thickness matters because it affects current flow, heat dissipation, and durability. Thin copper saves space, but thick copper boosts performance.

Dive Deeper: The Basics

I’ve seen boards fail because people ignored this. Copper carries electricity. Too thin, and it burns out. Too thick, and it wastes space. Here’s what I consider:

Current Flow

Thicker copper handles more current. I use it for power-heavy designs.

Heat Control

It spreads heat better. I pick thicker layers for hot components.

Durability

Thicker lasts longer. I’ve had thin boards crack under stress.

It’s about balance. I match thickness to the job.

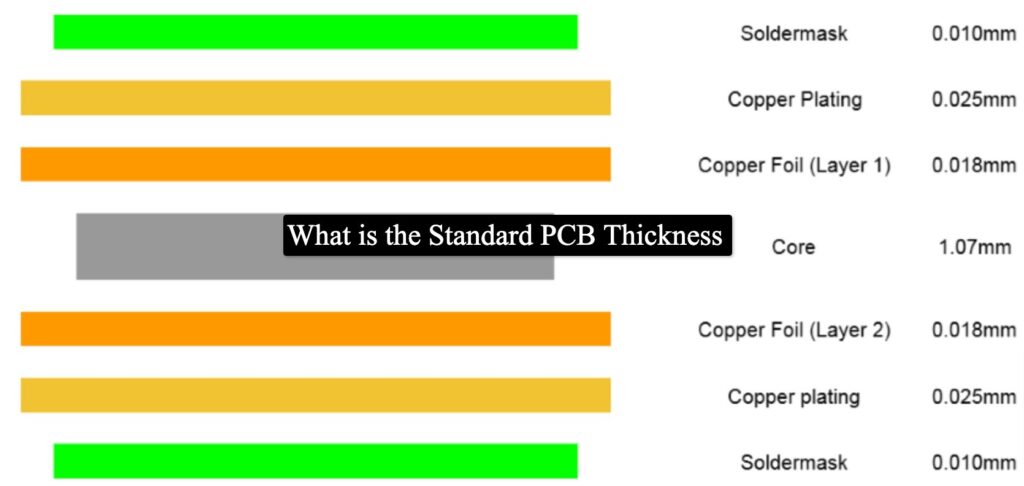

What Are Standard PCB Copper Thickness Options?

I often guide clients on this. Knowing standard options helps you pick fast. Let’s look at what’s out there.

Standard PCB copper thickness options are 0.5 oz, 1 oz, 2 oz, and 3 oz per square foot. Most boards use 1 oz—it’s a solid middle ground.

Dive Deeper: Breaking Down the Choices

I’ve tested these in production. Here’s my take:

| Thickness | Weight (oz/ft²) | Use Case |

|---|---|---|

| 17.5 µm | 0.5 oz | Small, low-power boards |

| 35 µm | 1 oz | General-purpose designs |

| 70 µm | 2 oz | High-current applications |

| 105 µm | 3 oz | Heavy-duty power boards |

I stick to 1 oz for most projects. It’s versatile. But I go thicker for power needs.

How Does Current Load Affect Copper Thickness?

I’ve burned out boards before. Current load is a big factor. Let’s see why it matters.

Higher current needs thicker copper. A 1 oz layer handles about 2-3 amps per trace width, while 2 oz doubles that capacity.

Dive Deeper: Current and Copper

I use a simple rule. More amps mean more copper. Here’s a table I rely on:

| Thickness (oz) | Max Current (amps, 10 mil trace) |

|---|---|

| 1 oz | 2-3 |

| 2 oz | 4-6 |

| 3 oz | 6-9 |

I check my design’s current first. Then I pick the thickness. It’s saved me headaches.

Can Copper Thickness Impact Heat Management?

I’ve felt boards get too hot to touch. Heat is a killer. Can copper help? Let’s find out.

Yes, thicker copper improves heat management. It spreads heat away from components, keeping your PCB cool under load.

Dive Deeper: Heat and Thickness

I’ve seen this in action. Thin copper traps heat. Thick copper acts like a radiator. For LED boards, I go 2 oz or more. It’s a game-changer for reliability.

Real Example

I built a power supply once. 1 oz overheated. Switched to 2 oz—problem solved.

I always ask: How hot will it get? Then I adjust.

How Do Cost and Size Influence Copper Thickness?

I’ve had clients push for cheap boards. Cost and size matter. Let’s see how they play in.

Thicker copper costs more and takes up space. Thin copper is cheaper and fits tight designs, but it limits power.

Dive Deeper: Balancing the Two

I weigh these every time:

Cost

1 oz is budget-friendly. I use it unless power demands more.

Size

Thin copper fits small gadgets. I’ve squeezed 0.5 oz into tight spots.

| Thickness | Cost | Size Fit |

|---|---|---|

| 0.5 oz | Low | Small |

| 2 oz | High | Large |

I ask: What’s the budget? What’s the space? Then I decide.

Conclusion

I’ve walked you through choosing PCB copper thickness. It’s about current, heat, cost, and size. Start with 1 oz for most jobs. Go thicker for power or heat needs. At TriWin PCB, we’ve been perfecting this since 2015. We’re here to help with reliable solutions.