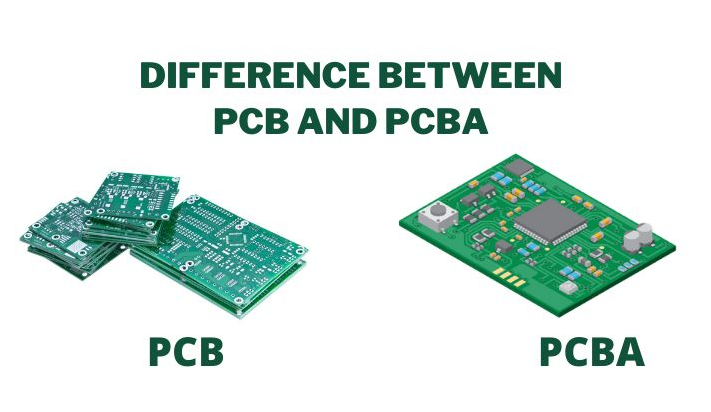

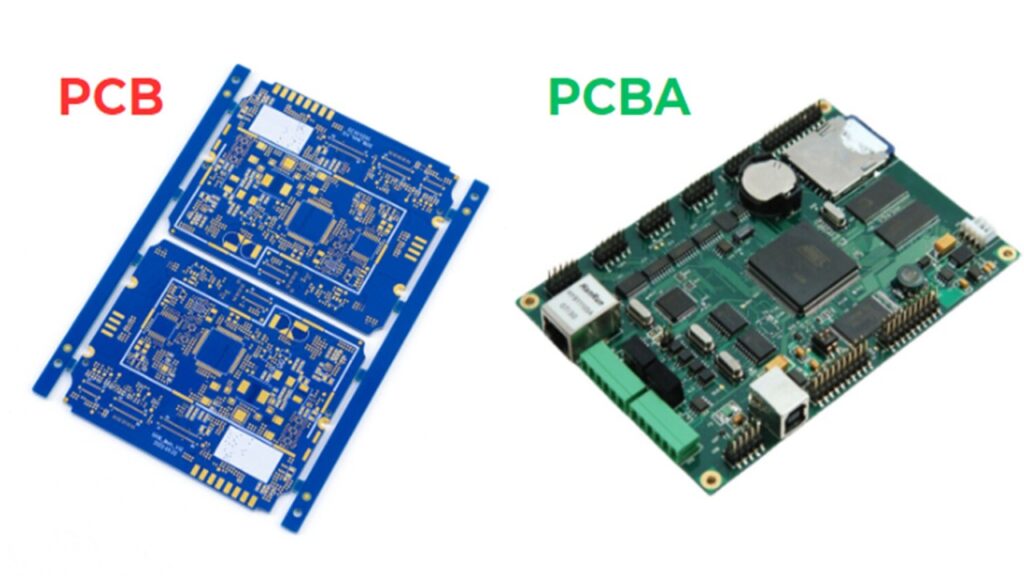

In today’s fast-paced world of technology, printed circuit boards (PCBs) are at the heart of most electronic devices. This article delves into the differences between a bare PCB and an assembled PCB—often referred to as PCBA—to help you gain clear insights into how electronic products are brought to life. For businesses and hobbyists alike, understanding PCB vs. PCBA can improve decision-making, efficiency, and ultimately, product quality.

Defining PCB

A plain PCB, or printed circuit board, is a foundational component in modern electronics. At its most basic level, a PCB consists of a board made typically from fiberglass or other substrate materials. Conductive pathways—traces—are etched or printed onto the board to form connections between electronic components. In this role, the PCB is the backbone of any electronic device, carrying signals that power internal circuits.

PCBs can vary significantly in complexity:

- Single-sided boards have components on one side only.

- Double-sided boards allow components and traces on both sides.

- Multilayer boards use multiple layers of material, enabling more intricate and higher-density designs crucial for advanced devices.

Every layer in a PCB has a specific function. The top and bottom layers contain copper traces, while the inner layers may serve as grounding planes or additional signal-routing surfaces. The precision and capability of these designs directly impact a device’s performance, durability, and cost.

Defining PCBA

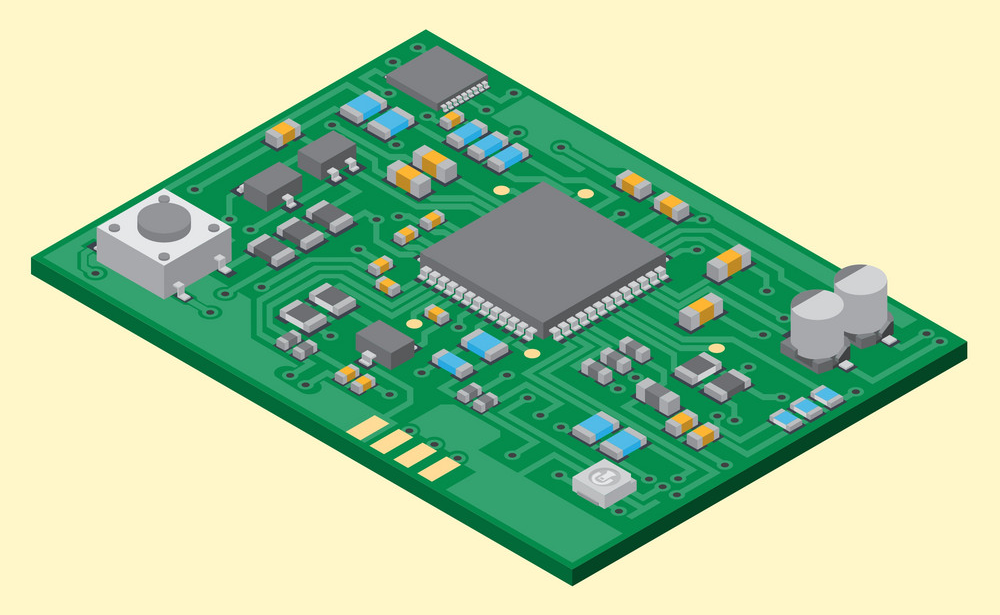

PCBA stands for Printed Circuit Board Assembly. In other words, it is the process of soldering or mounting electronic components onto the bare PCB. Without components, a PCB alone is just a structured board. By adding integrated circuits (ICs), resistors, capacitors, diodes, and other parts, the PCB transforms into a functional board that can power electric circuits in everything from computers to household appliances.

The assembly process typically includes:

- Surface Mount Technology (SMT): Components are placed directly onto the surface of the PCB.

- Through-Hole Technology (THT): Components have leads that pass through holes in the PCB before being soldered from the opposite side.

Whether one uses SMT or THT (or both), the goal is to adhere components to the PCB effectively and ensure reliable connections. The quality of the assembly process has a major influence on a product’s performance and longevity.

Key Differences Between PCB and PCBA

Manufacturing Processes

When producing PCBs, the main focus is on the layout and materials. From laminating fiberglass layers to photo-etching copper traces, the manufacturing remains highly technical yet exclusively devoted to creating a functional board architecture.

By contrast, PCBA involves the additional steps of component procurement and placement, soldering, and testing. Specialized equipment like automated pick-and-place machines ensures components are accurately positioned on the board. The manufacturing scope thus expands far beyond simple board production, incorporating activities that turn the PCB into a piece of working hardware.

Cost and Complexity

A bare PCB is often less expensive than a PCBA because it lacks the components and assembly labor. However, the complexity of the PCB design—number of layers, trace width, and required tolerances—still affects manufacturing costs.

PCBA tends to be higher in cost because it includes component sourcing, solder paste application, and various inspection processes. Errors in assembly are more critical, potentially resulting in an entire batch of defective boards. Hence, robust testing procedures (such as automated optical inspection and in-circuit testing) raise the cost but ensure quality.

Applications

PCBs themselves form the structural backbone and are used in nearly all electronic devices. A PCBA, on the other hand, is a finished or nearly finished product—ready for integration into the final device or system.

Whether you need a simple single-sided board or a highly sophisticated, multilayer, high-speed design, the considerations differ. A basic PCB might suffice for simple gadgets, while a PCBA is needed to evaluate complex product functionality and performance.

Quality Control Measures

Both PCBs and PCBA undergo strict quality checks. For the PCB, inspections involve ensuring proper etching, correct drill sizes, and adherence to layout tolerances. PCBA inspection adds multiple layers of complexity: verifying component placement, solder joints, and final circuit functionality. For PCBA, functional testing is critical because a single faulty component can render the entire board useless.

Detailed Comparison of PCB and PCBA

Material Choices

PCBs often use materials like FR-4 (a woven glass epoxy laminate) or, for specialized needs, metal substrates such as aluminum or copper for better heat dissipation. In PCBA, the choice of components is equally crucial, as it must align with the design criteria and thermal, mechanical, and electrical requirements of the end product.

Production Timeline

PCB manufacturing typically has a shorter timeline because it involves fewer stages. Once the design is finalized, boards can be produced relatively quickly. PCBA adds complexities: you must purchase or source components, program pick-and-place machines, handle potential lead time issues for specific parts, and conduct more extensive testing. All these steps can extend the total lead time.

Testing Procedures

- Bare Board Testing (BBT): Checks for open and short circuits on the PCB.

- Functional Testing (FCT): For assembly. Ensures the board operates to design specifications.

- Automated Optical Inspection (AOI) and X-ray Inspection: These help detect soldering defects and misaligned or missing components in assembled boards.

Outsourcing Considerations

Some companies handle PCB production in one factory and assembly in another. Others, known as one-stop service providers, do everything under one roof. Outsourcing PCBA to a single partner can streamline communication, reduce the risk of errors, and improve cost efficiency.

Common Misconceptions

Many people use “PCB” and “PCBA” interchangeably, though they are technically not the same. A PCB is a bare board, while a PCBA is a board with components fully assembled. Another misconception is that every product needs a complex board. In practice, the chosen design—single-layer, double-layer, or multilayer—should match the device’s functionality requirements and budget.

Importance of Selecting the Right Manufacturing Partner

A careful approach to selecting a PCB/PCBA partner impacts cost, quality, and time-to-market. A reliable manufacturer offers:

- High-precision equipment and thorough testing.

- Certifications such as ISO9001, IATF16949, and UL for quality and industry compliance.

- Engineering expertise to simplify design for manufacturability.

- Transparent communication channels for effective sourcing and assembly.

In addition, opting for a partner with specialized capabilities in producing high-frequency, metallic, or flexible PCBs can help ensure an end product that meets or exceeds your application requirements.

Final Summary and Next Steps

Understanding the difference between PCB and PCBA guarantees a clearer path from concept to product launch. In short, a PCB is the bare backbone that organizes electrical pathways, whereas a PCBA is the assembled product equipped with all necessary electronic components. Choosing the right type, materials, and assembly processes can drastically affect performance, reliability, and cost-effectiveness.

At TriWin, we specialize not only in manufacturing a wide range of printed circuit boards, from single-layer to HDI but also in delivering expertly assembled PCBA solutions to meet diverse industry needs. With certifications like ISO9001, IATF16949, ISO14001, and UL, our team is equipped to handle both high-volume and specialized, high-precision orders. Whether you require aluminum-based boards for improved heat dissipation or advanced HDI designs for complex electronics, our manufacturing expertise can support your goals effectively.

Feel free to reach out if you are interested in taking your project from concept to completion with a reliable partner. But even if you select another route, remembering these core differences between PCB and PCBA will help you make smarter, more efficient decisions along your product development journey.