1. Introduction

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing the foundation for connecting electronic components in countless devices. Among the various PCBs, ceramic PCBs have emerged as a crucial technology for high-performance applications. These specialized boards offer unique properties that make them indispensable in industries where standard PCBs fall short.

As electronics evolve, demanding higher performance in smaller packages, ceramic PCBs have become increasingly important. They offer solutions to challenges such as heat dissipation, signal integrity at high frequencies, and reliability in harsh environments. Understanding ceramic PCBs is essential for engineers, manufacturers, and anyone involved in cutting-edge electronics development.

2. Definition of Ceramic PCB

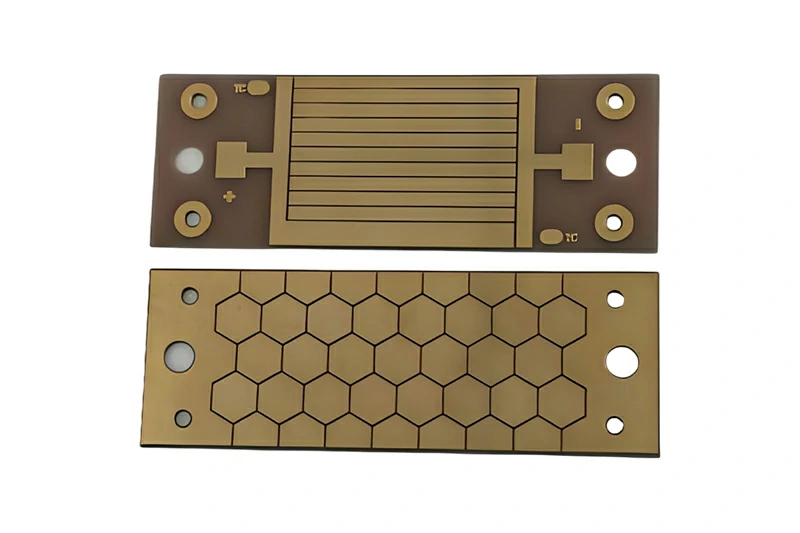

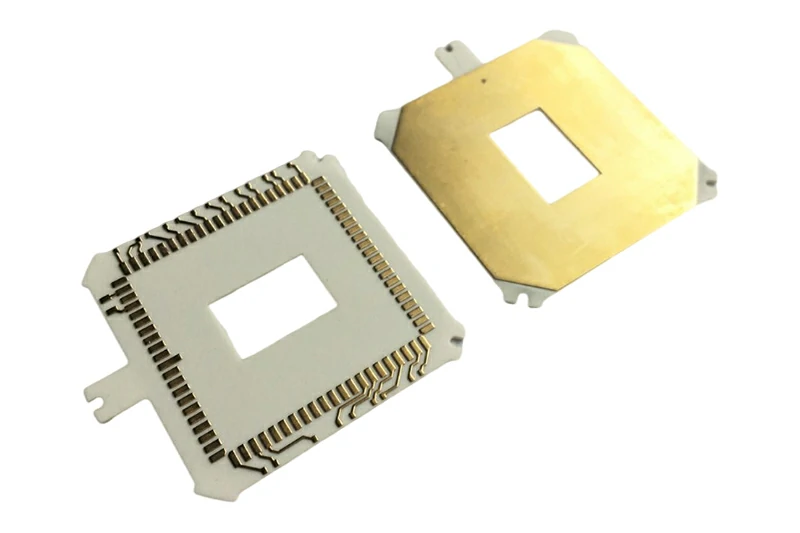

A ceramic PCB, or a ceramic substrate PCB, is a printed circuit board that uses a ceramic material as its base substrate instead of the more common FR-4 (fiberglass-reinforced epoxy laminate) used in traditional PCBs. The ceramic substrate provides a range of unique properties that make these PCBs suitable for specialized applications.

Ceramic PCBs are characterized by their excellent thermal conductivity, high dielectric strength, and superior mechanical properties. These attributes allow them to outperform traditional PCBs in high-stress, high-temperature, or high-frequency applications.

3. Types of Ceramic PCBs

There are several types of ceramic materials used in PCB manufacturing, each with its own set of properties and advantages:

Alumina (Al2O3) Ceramic PCBs

- Most common type of ceramic PCB

- Excellent electrical insulation properties

- Good thermal conductivity

- High mechanical strength

Aluminum Nitride (AlN) Ceramic PCBs

- Superior thermal conductivity compared to alumina

- Ideal for high-power applications

- Coefficient of thermal expansion close to silicon

Other Ceramic Materials

- Beryllium oxide (BeO): High thermal conductivity but toxic

- Silicon carbide (SiC): High thermal conductivity and strength

- Low-Temperature Co-fired Ceramic (LTCC): Suitable for multilayer designs

4. Manufacturing Process of Ceramic PCBs

Ceramic PCBs’ manufacturing process differs significantly from traditional FR-4 PCBs. Here are the key steps:

- Substrate Preparation: The ceramic material is formed into thin sheets or wafers.

- Metallization: A thin metal layer (usually copper) is deposited on the ceramic surface.

- Patterning: The circuit pattern is created using photolithography or screen printing.

- Firing: The board is fired at high temperatures to bond the metal to the ceramic.

- Plating: Additional metal layers may be added for improved conductivity.

- Finishing: Final surface treatments are applied for protection and solderability.

This process requires specialized equipment and expertise, so manufacturers like TriWin, with their ISO9001, IATF16949, ISO14001, and UL certifications, are well-positioned to produce high-quality ceramic PCBs.

5. Advantages of Ceramic PCBs

Ceramic PCBs offer several significant advantages over traditional PCBs:

Thermal Management

- Superior heat dissipation capabilities

- Ideal for high-power applications

- Reduces the need for additional cooling systems

Electrical Properties

- Electrical Properties

- Low signal loss at high frequencies

- Suitable for RF and microwave applications

Mechanical Strength

- High resistance to bending and breaking

- Maintains stability under thermal stress

- Suitable for applications with high vibration or shock

Reliability in Harsh Environments

- Resistant to moisture and chemicals

- Stable performance across a wide temperature range

- Long-term reliability in challenging conditions

6. Comparison: Ceramic PCBs vs. Traditional PCBs

To better understand the unique position of ceramic PCBs, let’s compare them to traditional FR-4 PCBs:

| Property | Ceramic PCBs | Traditional FR-4 PCBs |

| Thermal Conductivity | High (20-270 W/mK) | Low (0.3-0.5 W/mK) |

| Dielectric Constant | 6-10 | 4.2-4.8 |

| Coefficient of Thermal Expansion | Low (4-7 ppm/°C) | High (14-17 ppm/°C) |

| Maximum Operating Temperature | Up to 350°C | Up to 140°C |

| Cost | Higher | Lower |

| Typical Applications | High-power, high-frequency, harsh environments | General electronics, consumer devices |

This comparison highlights why ceramic PCBs are chosen for specialized applications despite their higher cost.

7. Applications of Ceramic PCBs

Ceramic PCBs find use in various high-performance applications across multiple industries:

Automotive Industry

- Engine control modules

- LED headlights and taillights

- Sensors in harsh environments

Aerospace and Defense

- Radar systems

- Satellite communications

- High-reliability avionics

High-Power LED Lighting

- Street lighting

- Industrial lighting

- Automotive lighting

RF and Microwave Devices

- 5G base stations

- Satellite communication equipment

- High-frequency test and measurement equipment

8. Challenges and Limitations

While ceramic PCBs offer numerous advantages, they also come with specific challenges:

Cost Considerations

- Higher material and production costs compared to FR-4 PCBs

- It may require specialized equipment for manufacturing

Design Complexities

- Different design rules compared to traditional PCBs

- Limited to simpler designs due to manufacturing constraints

Manufacturing Challenges

- Requires specialized knowledge and equipment

- Lower yield rates compared to FR-4 PCB production

9. Conclusion

Ceramic PCBs are essential for high-performance electronics, excelling in thermal management, electrical performance, and reliability in harsh environments. As devices advance, their importance will grow, though they may only replace traditional PCBs in some cases.

TriWin, with extensive experience and certifications in PCB manufacturing, is well-equipped to provide high-quality ceramic PCB solutions. Contact our expert team to learn how we can support your high-performance PCB needs.

FAQ

How do ceramic PCBs differ from FR-4 PCBs?

Ceramic PCBs use a ceramic substrate instead of fiberglass-reinforced epoxy. Compared to FR-4 PCBs, they offer superior thermal conductivity, better electrical properties at high frequencies, and improved reliability in harsh environments.

What are the main advantages of using ceramic PCBs?

The main advantages include:

- Excellent thermal management.

- Superior electrical properties at high frequencies.

- High mechanical strength.

- Reliability in harsh environments.

Which industries benefit most from ceramic PCB technology?

The industries that will benefit most are automotive, aerospace and defense, high-power LED lighting, and RF/microwave communications.

What are the key considerations when designing with ceramic PCBs?

Key considerations include thermal management, electrical performance at high frequencies, mechanical stress, and manufacturing limitations specific to ceramic materials.

How does the cost of ceramic PCBs compare to traditional PCBs?

Ceramic PCBs are generally more expensive than traditional FR-4 PCBs due to higher material costs and more complex manufacturing processes.

Can ceramic PCBs be used in multilayer designs?

Yes, you can use ceramic PCBs in multilayer designs, especially with Low-Temperature Co-Fired Ceramic (LTCC) technology. However, they usually accommodate fewer layers compared to FR-4 PCBs.